Ensuring Durability and Protection: The Significance of Puncture Resistance Testing

The puncture resistance test is a crucial evaluation method used to assess the ability of materials, such as films, laminates, fabrics, or packaging, to withstand puncturing forces. This test is conducted to ensure the durability and protective qualities of these materials in various applications. In this article, we will explore the significance of puncture resistance testing and its practical applications.

Understanding the Test: The puncture resistance test evaluates a material’s ability to withstand the force exerted by a sharp object without tearing or puncturing. It measures the material’s strength against puncture to ensure it can resist damage in real-world scenarios. The test determines the maximum force required to puncture a specified area of the material, and this value is used to assess its puncture resistance.

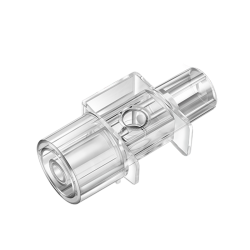

Test Procedure: To conduct the puncture resistance test, a sample of the material is clamped or secured, and a sharp object, such as a needle or a cone, is applied to the predetermined area with increasing force. The force required to puncture the material is measured, and the test is typically performed multiple times to account for any variance. The results provide insights into the material’s ability to withstand puncturing forces.

Applications:

Packaging Industry: The puncture resistance test is highly significant in the packaging industry. Packaging materials, such as films, bags, or shrink wraps, need to possess adequate puncture resistance to protect the contents from sharp objects or accidental impacts. By conducting this test, manufacturers can ensure the integrity of their packaging materials and prevent product damage during handling, transportation, and storage.

Textile and Fabric Industry: Fabrics used in various applications, such as protective clothing, upholstery, or industrial textiles, require puncture-resistant properties. This test helps manufacturers determine the puncture resistance of fabrics, ensuring they can withstand potential puncturing forces and maintain their protective qualities. It is particularly critical in industries where workers are exposed to hazardous conditions or sharp objects.

Construction and Geotextiles: Puncture resistance testing is essential in the construction industry, where materials like geotextiles are utilized. Geotextiles provide erosion control, drainage, and soil stabilization. Evaluating their puncture resistance ensures their ability to endure sharp objects in the ground or during installation, maintaining their functionality and longevity.

Safety Equipment: Puncture resistance testing is crucial for safety equipment, such as gloves, boots, or protective gear. It ensures that these products provide adequate protection against puncture hazards, reducing the risk of injuries in various industries, including construction, manufacturing, or healthcare.

Conclusion: The puncture resistance test is a vital assessment method used to evaluate the ability of materials to withstand puncturing forces and maintain their integrity. By subjecting materials to puncture forces, manufacturers can ensure durability and protection in various applications, including packaging, textiles, construction, and safety equipment. Puncture resistance testing is essential for maintaining product quality, preventing damage, and ensuring the safety of individuals, ultimately contributing to customer satisfaction and overall brand reputation.