Ensuring Safe and Resilient Packaging: The Importance of Packaging Drop Test

The packaging drop test is a critical evaluation carried out by manufacturers to assess the ability of packaging materials and containers to withstand impacts during handling, transportation, and storage. This test plays a crucial role in ensuring that packaged products remain intact and undamaged, providing a safe and satisfying experience for consumers. In this article, we will explore the significance of the packaging drop test and its practical applications.

Understanding the Test: The packaging drop test simulates real-world scenarios where packages may accidentally fall or experience impacts. It aims to replicate the conditions that packages may encounter during their journey from the production line to the end consumer. By subjecting packaging materials to controlled drops, manufacturers can evaluate their resilience and durability, helping them make informed decisions about packaging design and material selection.

Test Procedure: The packaging drop test involves dropping a package from a predetermined height onto different surfaces to assess its ability to withstand impact. The test is conducted using specialized drop test equipment, which allows manufacturers to precisely measure the forces and impacts experienced by the package during a drop. The height and surface used for the test may vary depending on the specific product or industry standards.

Applications:

E-commerce and Shipping: With the rise of e-commerce, where products are shipped directly to consumers, the packaging drop test has become increasingly important. The test helps determine if the packaging can protect the product during transportation, preventing damage from accidental drops or rough handling. By conducting this test, manufacturers can ensure that their packaged products reach customers undamaged, reducing returns and customer dissatisfaction.

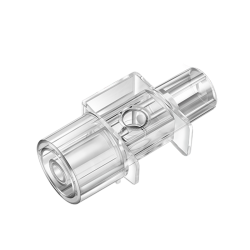

Fragile Goods and Electronics: Fragile goods, such as glassware, electronics, or delicate components, require special packaging to withstand impacts during transit. The drop test allows manufacturers to identify weaknesses in their packaging design and make necessary modifications to ensure the safety of the products. By conducting this test, manufacturers can reduce the risk of breakage or malfunctioning of sensitive items, ensuring customer satisfaction.

Food and Beverage Industry: Packaging plays a significant role in preserving the quality and freshness of food and beverages. The drop test helps manufacturers assess the integrity of packaging materials used for perishable items, such as glass bottles, cans, or plastic containers. By conducting this test, food and beverage companies can ensure that their packaging can withstand drops and impacts, reducing the risk of leaks, spoilage, or contamination.

Conclusion: The packaging drop test is a crucial evaluation method employed by manufacturers to assess the resilience and durability of packaging materials and containers. By subjecting packages to simulated drops, manufacturers can identify weaknesses and make necessary improvements to ensure the safety and integrity of their products during transportation, handling, and storage. The test helps reduce damages, customer complaints, and product returns, ultimately leading to enhanced customer satisfaction and brand reputation.