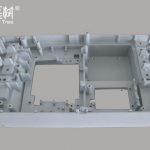

Flange Molding

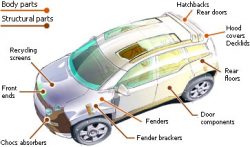

Flanged joint is the main connection method in pipeline construction. Compared to thermoplastic, thermoset composite can be reprocessed. With high insulating properties, Insulated flange is widely applied in petroleum and chemical and other industries. Flange molding is injection and pressure molded, delivering consistent quality.

Advantages of SMC/BMC Flanges

Insulation property required by buried pipeline

Long-term stable performance under hard conditions

High strength and airtightness

Simple structure, easy to assembly, dismount and change parts

Corrosion free

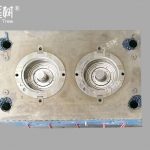

SMC Flange Moulding

Reduce human factor to a minimum in production

Compression molding shortens the delivery time and produce constant quality

Well-suited for mass production of small diameter flanges

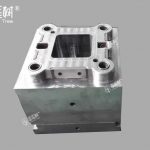

Flange Molding Surface Treatment

Outer surface is smooth and precise, needing no machining.

Interior surface can be machined according to requirements.

Flange Molding Specifications

Material

Based on requirements

Color

Custom and depending on requirements

Pressure rating

custom

Operation Temperature

Depending on molding

Flange Molding for You

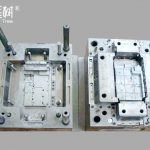

Insulation Mold

SMC Cable Braket Moulding

SMC Antenna Reflector Mould