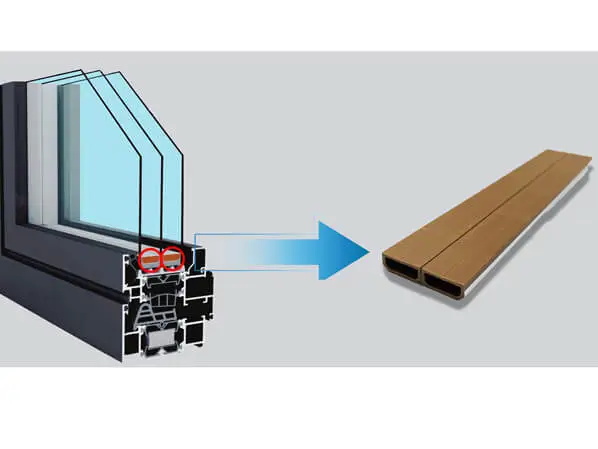

PE/PP/PVC Warm Edge Spacer Bar Extrusion Line

The energy-saving effect of the warm edge bar is better than the aluminum strip, the traditional aluminum strip is a cold edge method, because of its fast heat conduction and energy loss is fast, generally we say that any kind of spacing bar as long as its thermal conductivity is lower than the thermal conductivity of the aluminum spacing bar, it can be called the warm edge bar, there are many kinds of warm edge bars, stainless steel warm edge bar, glass fiber warm edge bar, stainless steel composite warm edge bar, these are rigid warm edge bars, Also like super interval strip, window edge to warm rubber strip and other flexible warm edge strip.

Warm edge strip: Using international high-end technology, the composite material is perfectly combined with stainless steel/aluminum through hot and cold co-extrusion technology. The strong performance of the warm edge strip is mainly reflected in fire prevention, dew resistance, low thermal conductivity and excellent bending performance.

Features of PE/PP/PVC Warm Edge Spacer Bar Extrusion Line

Low thermal conductivity to achieve excellent thermal insulation performance.

Significantly improve the uw value.

Improve the temperature of the insulating glass edge.

Strong anti-condensation and anti-mold function.

Effectively slow down the air flow near the window.

Anti-condensation and anti-ultraviolet.

Reduce heat loss.

Beautiful visual effect.

The invention of the warm edge strip updates the technical process of the spacer strip and makes up for the deficiency of the comprehensive performance of doors and Windows. Warm edge technology will play its own role in various fields, and it will be advocated for passive housing in the future.

Applications OF PE/PP/PVC Warm Edge Spacer Bar Extrusion Line

1. Insulated Glass Units (IGUs): The PE/PP/PVC warm edge spacer bar extrusion line is commonly used in the production of warm edge spacer bars for IGUs. These spacer bars help enhance the thermal efficiency of windows and reduce heat transfer between the panes, resulting in improved energy efficiency and reduced condensation.

2. Window and Door Manufacturing: The extrusion line is utilized in the production of spacer bars for windows and doors. These spacer bars provide structural support and thermal insulation, contributing to improved overall performance and energy efficiency of the windows and doors.

3. Curtain Wall Systems: PE/PP/PVC warm edge spacer bars are also used in curtain wall systems. These systems are typically found in commercial buildings and large-scale construction projects. The extrusion line produces spacer bars that provide thermal insulation and structural support in the curtain wall, helping to maintain the energy efficiency of the building.

4. Greenhouses: The extrusion line can be employed in the production of warm edge spacer bars for greenhouse structures. These spacer bars help to create a thermal barrier, retaining heat within the greenhouse and maintaining an optimal growing environment for plants.

5. Refrigeration and Cold Storage: PE/PP/PVC warm edge spacer bars can also be used in refrigeration units and cold storage facilities. The extrusion line produces spacer bars that help reduce heat transfer and increase the insulation properties of the units, ensuring efficient refrigeration and preservation of perishable goods.

6. Automotive Industry: The extrusion line may be utilized in the production of warm edge spacer bars for automotive glass. These spacer bars assist in reducing heat transfer and maintaining optimal temperature control within the vehicle, enhancing comfort and energy efficiency.

Overall, the PE/PP/PVC warm edge spacer bar extrusion line finds applications in various industries such as the production of IGUs, windows and doors, curtain wall systems, greenhouses, refrigeration units, cold storage facilities, and the automotive industry.