Plastic Profile Extrusion Line

This plastic profile extrusion line consists of Single Screw Extruder, Vacuum Calibration Table, Haul-off Unit, Cutter and Stacker, the producing line features of good plasticization, high output capacity, low power consumption, and etc. The main plastic profile extruder speed controlled by imported AC inverter, and temperature control by Japanese RKC temperature meter, vacuum pump, and traction gear reducer of the down.

stream equipment are all good quality products, and also easy maintenance. Replace different parts, stably extrude various types of different shapes and structures, such as PP PC PE PVC profile extrusion ABS PS TPU TPE, etc.

Types of Plastic Profile Extrusion Line

WPC Profile Extrusion LineWPC Profile Extrusion Line

The line is mainly used in an extrusion molding of WPC (PE & PP) wood-plastic products such as indoor and outer floor, guardrail, pallet, pavilion, corridor.

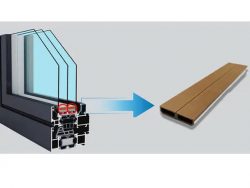

PVC Profile Extrusion LinePVC Profile Extrusion Line

Adopting new technologies, optimizing the unit, has the advantages of uniform plasticization, small shear rate, high yield, long service life, suitable for processing various types of plastic profiles.

Trunking Extrusion LineTrunking Extrusion Line

The production line is mainly used for extrusion processing of various industrial cable grooves, civil cable slots, cable bridges, and other products, can achieve online punching, printing, stickers and protective film, high extrusion efficiency, simple operation.

PVC/TPU/TPV/TPE Sealing Profile Extrusion LinePVC/TPU/TPV/TPE Sealing Profile Extrusion Line

The machine is used for producing sealing strip of PVC, TPU, TPE, etc material, features high output, steady extrusion, low power consuption. Adapting famous inverter, SIEMENS PLC and screen, easy operation and maintenance.

3D Printing Extrusion Production Line3D Printing Extrusion Production Line

The production line of JWell independently design is used for processing 3D consumables, car tubes,trachea and other products.

PVC Door Panel Extrusion LinePVC Door Panel Extrusion Line

The production line can produce the PVC wood-plastic door of the width between 600 and 1200 .the device has SJZ92/188 conical twin screw extruder, calibration, hall-off unit, cutter

PVC Wall/Ceiling Panel Extrusion LinePVC Wall/Ceiling Panel Extrusion Line

The machine is used for producing WPC decoration product, which is widely used in house and public decoration field, . It can be high quality decoration material for ceiling, door frame, window frame,…

Applications of Plastic Profile Extrusion Line

1

The PE / PP wood-plastic line is mainly used in PE / PP floor extrusion, PE / PP floor is widely used in outdoor parks, outdoor pavilions, etc. The production line can use different specifications of …

2

Mature applied to door and window profiles, plastic products such as fence and other plastic products. In various types of buildings, plastic windows, doors, floors, wall panels, ceiling have highligh…

3

Car seals are one of the important parts of the automobile, widely used in the door, window, body, skylight, engine box and backup (luggage) box, etc., with sound insulation, dust, anti-seepage and sh…

4

Jwell helps build a green ocean pasture! Traditional offshore box breeding is the main production information in wooden box, woody fishing and plastic foam. It will cause serious pollution to the sea …

Products

FAQ about Plastic Profile Extrusion Line

Can JWEEL companies offer plastic formulas?

JWELL machinery china company has more than 200 professional equipment engineers, can provide customers with relevant technical services.

What are your standard lead times?

Plastic Profile Extrusion Line Materials

This series of plastic profile extrusion line includes single screw extruders, vacuum calibration tables, traction devices, tools and stacker.

Extruder uses Siemens, ABB, and other imported inverters, Japan Omron temperature control form, France Schneider contactor, relay, electrical control system. German imported oil seals, molars, and other mechanical transmission systems. It can provide different design screws according to the characteristics of customer products, to deal with the requirements of plasticization. The fixed station uses special to increase the swirl current cooling system for cooling, special horizontal tilt control unique three-dimensional adjustment control, making it easier to operate. The tractor adopts unique lift technology, up and down track back pressure control, smooth work, good reliability, large traction. The cutting machine can be automatically fixed and configure dust recovery unit. Jwell’s 30-year experience in the industry, as well as the design of the entire product from the perspective of the operator, makes it easy to operate, easy to maintain.