Plastic Rapid Prototyping

Plastic Rapid Prototyping

Rapid prototyping is ideal for plastic parts that need to be a precise size or fit. To achieve precision, engineers and product developers will often need to test the plastic prototype multiple times within a short period to meet deadlines. Rapid prototyping, as the name suggests, offers this advantage.

Plastic PMMA Rapid Prototype

Transparent Rapid prototpe. We can choose PMMA (acrylic), transparent PC and other materials.These materials made out of the rapid prototype through high polishing, extremely high transparency, to achieve the same effect as the real product.

Acrylic is also one of the more materials used in rapid prototype processing, due to its transparent properties, They can be used to substitute glass on many parts.

Density

Mechanical Strength

Transmittance

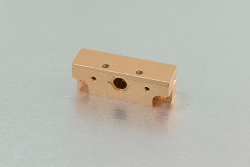

High temperature resistant hand plate

The PMMA has a lower density than the glass

The density of the PMMA, at approximately 1.15-1.19 g/cm3, It is half of the glass (2.40-2.80 g / cm3) and 43% of metallic aluminum (belonging to light metal).

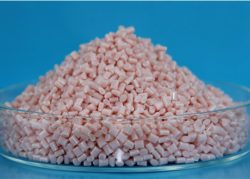

Plastic Rapid Prototyping Material Info

Plastic ABS Rapid Prototype

1

ABS is a thermoplastic polymer material with high strength, good toughness and easy processing. Because of its high strength, corrosion resistance and high temperature resistance, it is often used to make plastic shells for instruments. ABS plate usually has two kinds of light yellow and black, has a certain toughness, density of about 1.04 ~ 1.06g/cm3.

2

ABS has strong corrosion resistance to acid, alkali and salt, and can also tolerate organic solvent dissolution to a certain extent. ABS resin can perform normally in the environment of -25℃ ~ 60℃, and has good molding, the surface of the processed product is smooth, easy to Painting and electroplate. Therefore, it can be used in household appliances, toys and other everyday products.

3

Especially CNC processing of the first plate, ABS use of the scope of about 90%. Can be freely dismantled processing, the strength after bonding will not be greatly affected, this is a big reason why ABS material is popular in the plastic rapid prototype product processing industry.

ABS Materials Characteristics

Good impact resistance: only ductile deformation occurs when subjected to sudden attack.

High working pressure: the pressure is 1.0mpa at room temperature of 20℃.

The product has stable chemical properties, non-toxic, tasteless, and fully meets the health and safety requirements of pharmaceutical and food industries.

Large temperature range: the temperature range of its use is -20℃ ~ +70℃.

Light weight, saving investment: the weight of ABS is 1/7 of that of steel, thus reducing the weight of the structure, reducing the labor intensity of workers, and reducing the consumption of raw materials, which can greatly save the project investment.

Long service life: this product can be used for 50 years in the indoor, such as buried in the underground or water will have a longer life, and no obvious corrosion.