Specialty Epoxy Resins

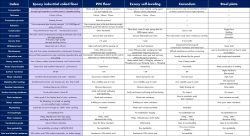

Tetra special epoxy resin offers two product categories with cycloaliphatic epoxy resin and glycidyl amine epoxy resin. These products have various features on dilution ability, glass transition temperature, adhesion, volume shrinkage, and migration. Therefore, they have been widely applied in UV-curing coatings/inks, adhesives, 3D printing, insulating castables, electronic packing materials, and other fields.

Advantages of Tetra Specialty Epoxy Resins

STRONG DILUTION ABILITY

01

There will be an obvious dilution effect when the addition amount in the formula exceeds 20%.

HIGH TG

02

The glass transition temperature (Tg) of cycloaliphatic epoxy resin is much higher than other common epoxy resins.

GOOD ADHESION

03

The products have excellent adhesion on a variety of substrate surfaces.

LOW VOLUME SHRINKAGE

04

The cycloaliphatic epoxy resin after UV curing is significantly lower than that of acrylate.

Why Choose Tetra Specialty Epoxy Resins?

Leading production capability in Shandong and Jiangsu bases can fulfill most of the downstream customer’s requirements.

Extensive product portfolio in cycloaliphatic epoxy resin with strong development capabilities and service capabilities.

Difference Between Cycloaliphatic Epoxy Resin & Glycidyl Amine Epoxy Resin

A

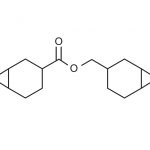

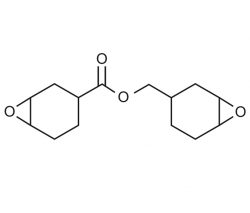

Cycloaliphatic epoxy resin

Cycloaliphatic epoxy resin is a series of products obtained by oxidation with butadiene and acrolein as base materials and the mixture of hydrogen peroxide and peracetic acid as oxidant.

B

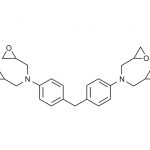

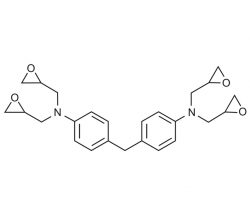

Glycidyl amine epoxy resin

Glycidyl amine epoxy resin is a series of epoxy resins having glycidyl groups attached to the aromatic amine. Such materials are prepared by the reaction of the aromatic amine with epichlorohydrin, followed by conventional dehydrochlorination.