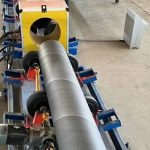

SPIRAL WELDED PIPE PRODUCTION LINE

Spiral welded pipe production line is used to manufacture spiral welded pipe. During the spiral steel pipe manufacturing, spiral welding pipe machine can produce steel pipes of different diameters with strips of the same width, and produce steel pipes of the same diameter with strips of different widths. Spiral pipe welding machine (spiral steel pipe machine) is mainly for front swing type and rear swing type. Our spiral welding pipe machine revolutionizes the industry with its cutting-edge technology and unparalleled efficiency. Contact us and get more information on spiral welded pipe manufacturing equipment!

SPIRAL WELDED PIPE PRODUCTION LINE FOR SALE

Large Diameter Spiral Welded Pipe Production Line

Read More

Small Diameter Spiral Welded Pipe Production Line

Read More

Heavy Duty Spiral Welded Pipe Production Line

Read More

Thin Wall Spiral Welded Pipe Production Line

Read More

Stainless Steel Spiral Welded Pipe Production Line

Read More

ADVANTAGES OF SPIRAL WELDED PIPE PRODUCTION LINE

High Production Efficiency: Spiral pipe welding machines are designed to produce pipes at a high rate of speed, which means that large quantities of pipes can be produced in a relatively short period of time.

Cost-effective: Spiral welded pipes are cost-effective compared to other types of pipes.

Versatility: Spiral welded pipes can be produced in various dimensions, lengths, and wall thicknesses, making them suitable for different applications.

High-Quality Pipes: Spiral welded pipe production lines produce pipes that meet high standards of quality and are durable.

Reduced Welding Defects: Spiral welded pipes are usually free of welding defects such as porosity, cracks, and lack of fusion, which means they are less likely to fail during use.

Easy Maintenance: The welded pipe production line used in the production line are designed for easy maintenance, reducing downtime and increasing productivity.

Preservation of Natural Resources: Spiral welded pipes are usually made of recycled materials, which reduces the use of natural resources.

Enhanced Safety: Spiral welded pipes are strong and durable, which enhances safety in various industries, including oil and gas, water supply, and construction.

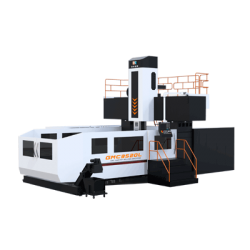

MACHINES AND EQUIPMENT MAINTENANCE OF SPIRAL WELDED PIPE PRODUCTION LINE

Regular cleaning: The spiral pipe making machine should be regularly cleaned to prevent the accumulation of dust and debris, which can lead to malfunctions and reduced efficiency.

Lubrication: The machines should be well-lubricated to prevent damage from friction.

Inspection: Regular inspection of the machines should be done to check for any signs of wear and tear, loose bolts, cracks or other damages, and address them promptly.

Calibration: Equipment calibration should be done as recommended by the manufacturers.

Replacement of worn-out parts: Worn-out parts should be replaced promptly to prevent damage to other parts and avoid downtime.

Operator Training: Operators of the machines should be trained on proper machine handling and maintenance.

Record-keeping: Recording maintenance activities, including repairs, calibration, inspections, and replacements of parts can help identify patterns in machine malfunctions and assist in scheduling future maintenance.

Upgrade equipment: Upgrading steel pipe machine and equipment can help improve efficiency and reduce operational costs, given that the latest machines are likely to consume less energy and require less maintenance.

THE IMPACT OF SPIRAL WELDED PIPE PRODUCTION LINE ON THE PIPE MANUFACTURING INDUSTRY

Increased production: The spiral welded pipe production line can produce large quantities of high-quality pipes at a fast rate, which has increased the overall production in the pipe manufacturing industry. This has also helped manufacturers to meet the increasing demand for pipes, especially in the oil and gas, water supply, and construction industries.

Reduced costs: The production of spiral welded pipes is less expensive than other pipe manufacturing methods, such as seamless and longitudinally welded pipes. This has helped to reduce the overall production costs while maintaining high-quality standards.

Versatility: Spiral welded pipe production lines can produce pipes in different dimensions, lengths, and wall thicknesses, making them suitable for various applications.

Improved efficiency: The automation of spiral welded pipe production lines has improved efficiency by reducing labor costs, reducing downtime, and increasing production speed.

Increased competition: The spiral welded pipe production line has increased competition in the pipe manufacturing industry, which has encouraged manufacturers to improve their processes and products to remain competitive.

Environmental impact: The production of spiral welded pipes is more environmentally friendly as it uses recycled materials, reducing the usage of natural resources.

https://www.txhmachine.com/products/spiral-welded-pipe-production-line/