assava Flour Machine

Features of Cassava Flour Machine

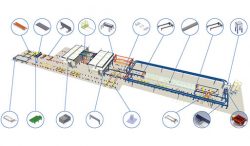

Cassava Flour Production Process Description and Flowchart:

Cassava flour is also called cassava whole flour, which is the fine powder, a little yellowish and grayish. Cassava flour is different from cassava starch. Cassava flour is made of whole cassava root, which keeps the natural cassava flavor and nutrition and contains more nutrient content than cassava starch. Cassava flour is a very popular food in most African countries. Cassava flour is widely used in people’s daily life for making bread and cakes. Now more and more people in different countries and regions begin to like the food made of cassava flour.

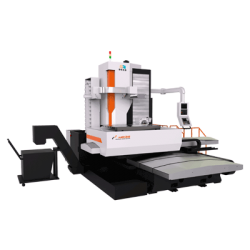

Goodway is an expert in design and providing cassava flour machine and cassava flour processing line since 1991. Some customers also call our cassava flour production process equipment as cassava flour equipment, cassava flour making machine, or cassava flour production machine. Anyway, we devote ourselves to providing high-quality cassava flour making machines with competitive price.

Multiple distinct operations are required in cassava flour production line: washing, peeling, grating, de-watering, breaking & sifting, cassava flour drying, milling, and packaging. According to the production line, GOODWAY provides related machines, including the cassava root harvester, cassava sieving machine, cassava skin peeling machine and cassava slicer, etc..

We provide below a brief description showing how to process cassava flour.

Cassava Flour Production Process

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It’s the first step of the cassava flour process and very important for the quality of final cassava flour(HQCF).

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Grating Peeled Cassava Roots into Mash

Load the grater with washed roots while the engine is running to grate peeled cassava roots into mash. The grating drum and all food contact areas should be made from stainless steel.

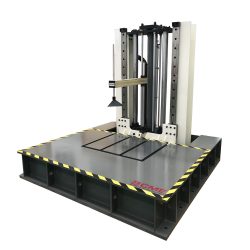

De-watering Mash into Wet Cake

Load the bags directly on to a hydraulic press. Lift and press the jack handle up and down until it becomes hard to move. Repeat the process several times each day until no more water comes out of the bag to produce a firm wet cake.

Breaking Wet Cake and Sifting Wet Cake into Grits

Breaking the wet cake into small pieces (grits) and remove the lumps to obtain uniform size grits(wet coarse cassava flour). All food contact areas should be made from stainless steel.

Drying Grits into Dried Coarse Cassava Flour

Effectively dry the wet grits into dried coarse cassava flour(HQCF) with low moisture content by the principle of heat transfer exchange. The drying process is more reliable and of higher quality.

Milling Coarse Flour into Fine Flour(HQCF)

Milling the dried coarse cassava flour into fine cassava flour(HQCF) with the uniform size, then pour the flour into a plastic lining inside a woven polythene sack.