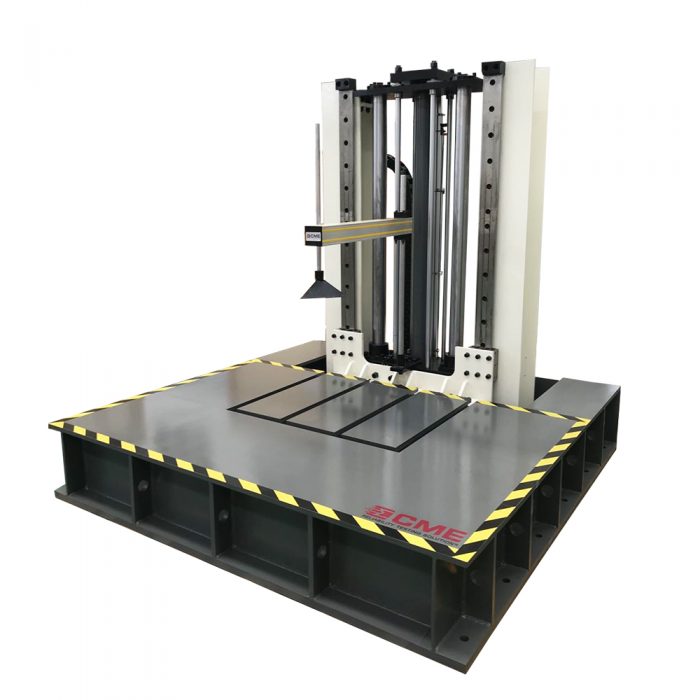

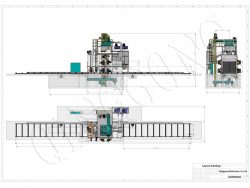

KRD40 Zero Distance Drop Test Machine

KRD40 series zero-distance drop tester is a single lifting servo motor driving drop test machine, which is mainly used for packaging goods that will be impacted by a vertical drop during transportation and handling operations. The packaged goods are subjected to standardized tests (face drop, angle drop, edge drop, etc.) to collect data, for the design of cushioning and vibration reduction, and the selection of packaging materials provide a design basis. It is applicable for electronic products, plastic products, toy products, packaged products, and unpacked products, to evaluate the impact strength of the product during handling or the damage caused by the drop, and to evaluate the impact resistance during transportation and handling procedure.

FEATURES OF KRD40 ZERO DISTANCE DROP TEST MACHINE

Servo closed-loop motor drive, simple structure, high reliability, smooth lifting

Adopt a single fully automatic lifting method, and the drop height is adjustable

PLC control is stable and reliable, the drop height can be accurately tracked and displayed in real-time

Handheld pad + human-computer interaction software, easy to operate

It can realize the drop test of the edge, surface, and angle of the sample

True color full touch screen operation, convenient and quick

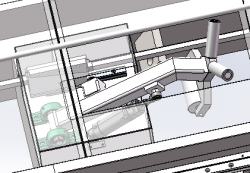

Adopt the E-fork structure to rise and fall, and the E-fork tray moves up and down under the control of a servo motor and a screw roller

TABLE OF KRD40 ZERO DISTANCE DROP TEST MACHINE

KRD40 zero-distance drop test table is mainly composed of an impact plate, lifting system, a working table, guide column, fixtures, displacement sensor, release mechanism, etc.

The working principle of the vertical drop test system can be briefly described as the lifting cylinder lifts the working table and the test piece to a certain height, and is released by the electromagnetic release mechanism. Since the work surface adopts a compressed energy storage spring during the lifting process, the work surface falls at a speed greater than the falling speed of the test piece. The test piece keeps its original state (face, edge, and corner) and falls freely, collides with the bottom plate, and completes the test requirements.