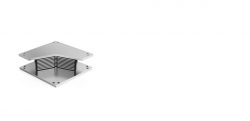

Cassava Desander and Desilter

Features of Cassava Desander and Desilter

Processing Capacity: 10-20m3/hour

Application Scope: Remove the sand and silt from the starch slurry

Product Introduction: Cassava processing machine, desander, and desilter, the desanding cyclone for cassava starch processing

1. No moving part

2. High wear resistance

3. High performance and efficiency

4. Very low maintenance

5. Easy installation

6. Low-cost separation

Product Description of Desander and Desilter

Solid control equipment that separates sand and silt from the raw starch milk. Desander is installed before the desilter and normally the solids diameter for desander to be separated would be larger than for desilter.

Product Application of Desander and Desilter

1. Sand and silt separation from cassava starch slurry

2. Sand and silt separation from potato starch slurry

Technical Parameters of Desander

Model no.

GD-CS-3

Production capacity

20m3/hour

Sand removal rate

≥99%

Working voltage

380V/50Hz 3Phase

Motor power

Hydraulic cyclone series

3

Cyclone cone angle

8.90

Working pressure

0.25-0.4MPa

Inlet/Outlet diameter

40mm

Separation size

45-74μm

Dimension(L×W×H)

950×600×1800mm

Weight

32kg

Technical Parameters of Desilter

Model no.

GD-CN-7

Production capacity

10m3/hour

Sand removal rate

≥99%

Working voltage

380V/50Hz 3Phase

Motor power

7.5kw

Hydraulic cyclone series

7

Cyclone cone angle

8.80

Working pressure

0.25-0.4MPa

Inlet/Outlet diameter

60mm

Separation size

15-44μm

Dimension(L×W×H)

600×400×1250mm

Weight

88kg