Rapid Prototyping Services

Rapid Prototyping Services are mainly divided into 3D printing and CNC Rapid Prototyping. Rapid prototypes or quick prototyping is a manufacturing technique for rapid prototype manufacturer to rapidly generate models or parts. Under the control and management of computer, relying on the existing CAD data, the rapid prototyping material is precisely piled up, the point is piled up into the surface, and the surface is piled up into three dimensions, and finally the entity is generated. It is possible to create very complex entities for China rapid prototype factory without the mold.

Fast Prototyping/Rapid Prototyping vs 3D Printing

Rapid prototypes is a fast, cost-effective way of creating prototypes for new products. Instead of creating a product and then testing it in order to improve it, rapid prototyping technologie allows you to test the product throughout the rapid prototyping manufacturing process. This reduces the risk of major errors or flaws occurring later in development. It’s common for rapid prototype manufacturers to use different types of Rapid Prototyping methods to create their prototypes depending on what they’re trying to accomplish with each project. Rapid prototyping manufacturing is a group of technologies that create a physical object from a computer-aided design (CAD) model. The key idea behind rapid prototypes is to build up layers of material by computer control instead of manual labor or traditional manufacturing techniques. This allows for parts to be created more quickly than other methods because both time and money are saved from not having a human operator manually creating each part individually by hand.

There is a lot of confusion surrounding the difference between 3D printing and rapid prototyping. While both terms are used interchangeably with one another, they are different processes.

3 D printing service is a subset of rapid prototypes which uses layers to build an object. The process is slower than rapid prototyping and can take hours or even days to create something. With this type of printing, there are no limitations on the amount of time needed for 3 d rapid prototype suppliers to produce your part because it all depends on how many layers will be needed in order for your part to be produced properly.

Some common materials that are used in 3 D printing service include ABS rapid prototyping, polypropylene, rubber and glass filled nylon. Rapid prototyping is the process of creating a prototype using different methods, such as: Stereolithography (SLA rapid prototyping services) , Selective laser sintering (SLS rapid prototyping process), Liquid resin infusion, which uses heat and pressure to fuse the powdered material into a solid piece.

Rapid Prototyping Technology Selection And Application

3D printing rapid prototyping process is a tool used to create 3D models and prototypes quickly, easily and at low cost of prototyping a product. It’s been around since the 1980s but has seen exponential growth since then due to advancements in technology; it’s now one of the most commonly used manufacturing techniques around the world.

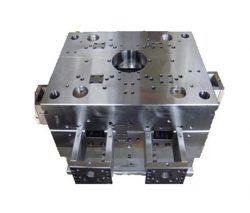

Rapid prototypes is mainly used for modeling parts that are difficult or expensive to make using traditional methods like CNC machining or mold injection molding (MIM). Because rapid prototypes creates a physical model rather than an image on screen, you can hold your part in your hand before it’s even made so you know exactly how it will look when finished. This makes rapid prototyping ideal for creating new products or testing out ideas before committing time or money into full production runs – which also helps rapid prototype supplier reduce waste when designing various iterations until you get it right.

Rapid Prototyping Technology Application includes the following:

Stereolithography (SLA rapid prototyping process) – The SLA printer uses lasers to trace the cross section of a model in layers. A vat of liquid resin hardens around each layer as it is traced. The process continues until an entire object is completed.

Fused Deposition Modeling (FDM rapid prototyping services) – Material extruded through a heated nozzle melts polymers or other materials which are deposited onto a platform in successive layers and then fused together by a laser beam or electron beam from below. This FDM rapid prototyping process can be repeated until an entire object is complete.

Difference Between Traditional Prototyping And Rapid Prototyping

Traditional prototypes were expensive because they took long to produce and involved a lot of heavy duty equipment. The more complex the product, the more time it would take to make a prototype. This meant that companies had to allocate large sums of money for prototyping purposes and would have little left in their budget for actual production.

https://www.gjprototyping.com/rapid-prototyping-services/