Eaton Char-Lynn Motor – Gasoline Motor Technology Trend

The invention of the internal combustion motor has driven the development of the automobile and brought great convenience to the world in terms of “walking”, which has narrowed the distance and improved the speed of people’s work. In recent years, with the development of electronic technology, the automobile motor has become more powerful and has become a high-tech integration. Eaton Char-lynn Motor illustrates the development of technology trends for gasoline motors

I. Development status of world gasoline motor technology

In order to meet the needs of automobiles for fuel economy, environmental protection and safety, the gasoline motor for vehicles is mainly developed in a more fuel-efficient and environmentally friendly direction. Therefore, Europe has implemented the Euro IV standard. The following are the main advanced technologies in foreign countries for gasoline motors.

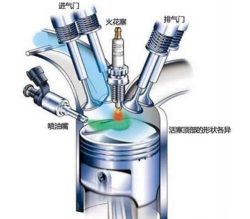

1. Multi-valve technology: 3-5 valves per cylinder (mostly 4 valves), can improve power and improve combustion quality, such as Jetta 5 valves, Toyota 8A4 valves.

2. Dual overhead camshafts (D.HC) increase speed and increase reliability.

3. Variable valve timing (VVT): When adjusting the valve according to different speeds, it can save fuel and improve emissions, such as Honda VTEC and Toyota VVT-i.

4. Gasoline motor boost: It can increase the power and increase the power when the displacement is constant, such as the Passat 1.8T sedan.

5. Variable Inlet Length (VIM): Use different inlet lengths at different speeds to ensure better aeration efficiency under any operating conditions, such as the Audi A6.

6. Cylinder stop technology: When the output power is reduced, some of the cylinders are stopped, which can save fuel. For example, the general pioneer EXT 2005 has 8 cylinders, and 4 cylinders can be stopped when needed.

7. All-aluminum motor: use aluminum cylinder block, cylinder head, piston, etc., can reduce the quality and save fuel, such as Japan Suzuki 1.3L, 1.4L gasoline motor.

8. Intelligent Drive Valve (SVA): Instead of a conventional camshaft, each valve lifter has a separate drive that reduces fuel consumption and contaminants by 20%. For example, French Valeo has designed a prototype and can be mass-produced in 2009. Put into production.

9. Variable compression ratio gasoline motor: Integrates transmission power with compression ratio control function, and the compression ratio is variable. In 2005, the French MCE-5 company has developed a prototype.

10. Gasoline direct injection (GDI) and lean combustion technology: direct injection of high-pressure gasoline into the cylinder, surrounded by a thin mixture of gas, to achieve stratified combustion, can improve fuel economy, fuel economy is about 20%, such as Toyota Huang. Crown 3.0L V6 gasoline motor (domestic crown without GDI technology).

11. Controlled Combustion Rate System (CBR): Two inlets, one with tangential air intake and the other with neutral. The injector injects the same amount of fuel into both inlets. By changing the position of the air inlet closed control valve, the air vortex intensity and the mixture concentration in the cylinder can be adjusted to achieve lean combustion;

12. The motor control ECU has reached 32 positions and the matching parameters exceed 6000.

Second, the status quo and development level of domestic gasoline motor technology

Most of China’s early gasoline motors were imported and surveyed imitation products, such as: CA6102 for FAW Jiefang trucks, BN492Q for BJ2020 vehicles, and 6427 for Nanqi light trucks. After the establishment of Sino-foreign joint ventures and technology introduction, China’s auto industry has produced a variety of models, such as: Cherokee BJ498Q, BJ698Q (2.5L, 4.0L); Santana AEE (1.8L); Passat AWL (1.8L); Beijing Hyundai Elantra B4GB (1.8L); Tianjin FAW Xiali TJ376Q (LOL); Changan Alto JL368Q (0.8L); Guangzhou Toyota Camry (Toyota 2.4L); Guangzhou Honda Accord (2.0L, 2AL, 3.0L); Guangzhou Honda Fit (1.3L, 1.5L); Dongfeng Nissan (1.6L, 1.8L, 2.0L); Chrysler CA488 (2.2L) produced by FAW Car; technology introduced by Mitsubishi 4G63, 4664 (2.0, 2.4L) 4669 series gasoline motor; Mitsubishi 4G1 (1.3L, 1.6L), 4G9 (1.8L, 2.0L) introduced by Dongan Power; Dongfeng Yueda Kia Maxima (1.6L), and 491Q produced by domestic Shenyang Xinguang, Baoding Great Wall and other enterprises Toyota 4Y), JL376 (LOL) and JL479 (1.3, 1.50, JL481 (1.8L) gasoline motors produced by Geely.

In terms of technical applications, most of the models imported from models and joint ventures use advanced foreign technology.

1. Tianjin Toyota 8A, 5A, Dongfeng Honda, Beijing Hyundai, Chery SQR372 (0.8L), SQR481Q (1.6L), Shenlong Elysee (1.6L), etc. all use multi-valve and DOHC technology.

2. Dongfeng Honda motor, Tianjin Toyota motor Co., Ltd. produced Corolla, Crown gasoline motor, Dongfeng Nissan, Beijing Hyundai and other gasoline models have introduced variable valve technology (VTEC, VVT-i, CVVT, etc.). In particular, Chery, the self-owned brand 1.6LSQR481H and 2.0L SQR484H gasoline motor developed with the help of AVL, used VVT variable valve technology, and Geely also developed a self-owned gasoline motor with variable technology.

3. Gasoline direct injection (GDI) motors have not been mass-produced domestically, but the self-owned brand 2.0L SQR484J gasoline motor developed by Chery with the help of AVL has used GDI technology.

4. There are many domestic products for all-aluminum motors, such as Changan Suzuki Swift 1.3L gasoline motor, Dongfeng Honda motor products, Shanghai Volkswagen POLO motor, Chery Power 1.6L SQR481F (commissioned) and SQR481 H and uncommissioned SQR484J, SQR681 V (2.4 L) and SQR684V (3.0L) are all aluminum motors.

5. The self-owned brand SQR481H (1.6L), which has been put into production by Chery, has a CBR system. Many models of Chery’s other prototypes are also equipped with a CBR system.

6. Many models in the domestically introduced models have adopted turbocharging technology: such as PASSAT 1.8T, Bora 1.8T, etc.; the 1.8T gasoline motor developed by Brilliance Gold Cup with the help of German FEV company is also a supercharged machine type ( Equipped with a Chinese car).

7. Technologies such as cylinder deactivation technology, intelligent valves, and variable compression ratio have not been adopted in domestically produced gasoline motors.

8. The motor EFI management system (EMS) mainly includes United Electronics Co., Ltd. and Beijing Wanyuan Delphi motor Management System Co., Ltd., which are joint ventures between China and Germany BOSCH and China and Delphi. At the same time, there are also companies such as Marelli, Denso and Motorola.

9. In the gasoline electromechanical spray system, sensors, electronically controlled fuel injection pumps, etc. have been mass-produced domestically; three-way catalytic converters and ceramic cores in gasoline motor exhaust systems have been mass-produced in China, such as: Dalian Huake Gillette, Tianjin Cadaco High-tech The technology company produces three-way catalytic converters; the Japanese-owned company NGK (Suzhou) Environmental Ceramics Co., Ltd. in Suzhou produces three-effect catalytic converter ceramic cores for national III and national IV gasoline motors.

Third, the continuous increase in automobile production caused a series of problems

The total global car ownership will increase from the current 800 million to 1.2 billion in 2020. In the middle of the 21st century, it will reach 3.8 billion, of which the car ownership in developing countries will increase by more than 15 times. At present, there are about 64 million new cars produced every year in the world. According to the average annual consumption of 10 to 15 barrels of oil and petroleum products per vehicle, the oil consumption of automobiles is 85 to 12.7 billion barrels per year, accounting for about the world’s oil production. half. The exploitation of petroleum resources amounts to several billion tons per year. After long-term modernization and large-scale exploitation, oil resources are depleted. According to scientists’ prediction, the oil resources on the earth can only last for 60 to 100 years according to the current mining level. In 2007, China imported 190 million tons of oil. It is estimated that by 2020, China’s oil imports may exceed Japan and become the largest oil importer in the Asia-Pacific region. The Development Research Center of the State Council predicts that by 2010 and 2020, China’s automobile consumption of oil will be 138 million tons and 256 million tons, accounting for 43% and 67% of the country’s total oil consumption. Therefore, the energy crisis is an important issue that we must face.

The growth in car ownership has brought many problems, such as health threats, environmental pollution, climate change, energy shortages and traffic congestion. At present, air pollution has become a very serious problem in urban areas. The harmful emissions of automobiles have caused a public damage to the living environment of human beings. According to the data, 60% of the atmospheric pollutants in urban areas come from automobile exhaust. Global warming and climate change are attracting more attention, and the corresponding carbon dioxide emissions will become the main problem for automakers to solve. Around 2010, the balance of supply and demand of energy in developing countries will lead to fluctuations in world oil prices. While ensuring environmental protection, vehicles using alternative energy sources will become the focus of automobile manufacturers.

In 2008, the EU required car CO2 emissions to reach 140 g / km, for gasoline vehicles, the corresponding fuel consumption will reach 6 liters / 100 km; in 2012, CO2 emissions requirements reached 120 g / km. Therefore, reducing fuel consumption and reducing emissions will be an urgent problem for the automotive industry.

Fourth, the development trend of gasoline motor technology

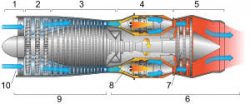

Since the fuel economy of gasoline motors is worse than that of diesel motors, reducing the energy consumption of gasoline motors has become a problem that must be solved in the automotive industry. The combustion theory of a homogeneous mixture with a theoretical air-fuel ratio is widely used in spark-ignition motors. Its greatest advantage is that it can be used as a three-way catalyst to reduce emissions of CO, HC and NOx. The downside is that high fuel economy cannot be achieved, and combustion technology is constantly evolving in order to improve the thermal efficiency of the motor and reduce exhaust emissions. The gasoline motor has undergone a change from the fully mechanically controlled carburetor oil supply to the use of electronically controlled injection, in-cylinder direct injection, electric auxiliary boost and electric valve, variable compression ratio, cylinder deactivation, etc. The solution will use combustion control technology that combines the advantages of gasoline and diesel motors.

The three most representative gasoline motor technologies are:

a. Gasoline direct injection technology. It is a major research goal to develop an motor with the advantages of a gasoline motor and the fuel economy of a part of the diesel motor. Direct injection in gasoline cylinders is an important means to improve the fuel economy of gasoline motors. In recent years, the research and application of a new mixed gas formation mode represented by Gasoliine Direct Injection (GDI) has greatly improved the gasoline motor. Fuel economy. The non-homogeneous direct injection technology represented by Japan faces problems such as combustion stability and post-treatment, and homogeneous direct injection technology represented by Europe is emerging.

b. Electric and camless motors. Variable Valve Timing (VVT) is designed for use in conventional automotive motors where certain important motor performance is not adequately met throughout the operating range due to fixed valve timing. . VVT technology provides the best valve timing in the range of motor operating conditions, which better solves the contradiction between high speed and low speed, power and economy under heavy load and small load, and at a certain extent to a certain extent. Improved emissions performance. With the requirements of environmental protection and sustainable human development, low energy consumption and low pollution have become the development goals of automotive motors. Due to its own advantages, VVT technology has been paid more and more attention, especially the rapid development of electronic technology, which promotes the development of VVT technology from the research stage to the practical stage. Electric valves have the same important meaning as electronically controlled injections. They will bring a series of technological changes to motor air system control and cycle process management, such as canceling the throttle, variable compression ratio, and partial cylinder deactivation.

c. Mixing of combustion methods. The combustion process of a conventional spark-ignition motor is much higher in the flame propagation than the unburned mixture. Therefore, this combustion process is uniform even when the gas mixture is mixed, but the temperature distribution is still uneven, and local high temperature causes NOx to form in the region where the flame passes. The combustion process of a diesel motor is a diffusion type. The combustion rate in the combustion process is determined by the mixing rate. The ignition occurs at many points. This type of combustion process is uneven in mixing and combustion, and NOx is generated in a relatively high temperature region where combustion occurs. Solid particles are produced in a high temperature zone where the fuel is concentrated. In the Homogeneous Charge Compression Ignition (HCCI) process, theoretically a homogeneous mixture and residual gas, ignited by compression throughout the mixed gas, the combustion is spontaneous, uniform and without flame propagation, This prevents the formation of NOx and particulates. This kind of gasoline motor homogenization is combined with diesel motor compression ignition. Based on fuel technology and control technology, the homogeneous compression ignition HCCI internal combustion motor technology that combines the advantages of both gasoline motor and diesel motor is emerging.

The continued development of automobile production faces many problems, and reducing fuel consumption and carbon dioxide emissions will become major problems for automakers. With the improvement of the performance of the gasoline motor electronic control system, it is believed that we will use more energy-efficient and higher-performance cars in the near future.

https://www.xjetl.com