JimaFor Precision Machining

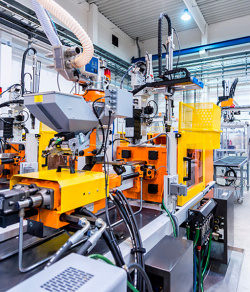

Precision machining is JimaFor most important core competitiveness. It is not a workshop, but a factory with advanced and complete equipment, a complete management team, and independent engineering, production, quality and supply chain teams. JimaFor provides customers with precision machined castings, forgings, stampings machined parts.

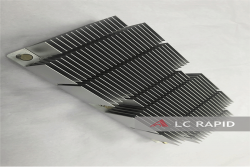

We operate almost every kind of CNC mill and turning center, and pride ourselves on being able to machine whatever you need, from simple, ‘as-machined’ Workholdings to complex, organic geometries with tight tolerances. On request, we can also produce parts with EDM and grinders. Build envelopes, minimum feature sizes and design guidelines vary for milling and turning.

To ensure the highest quality of the finished product, it is crucial to use computer programs. CAD (Computer-Aided Design) CAM (Computer-Aided Manufacturing) programs provide detailed working drawings of each step of the precision machining process. Programs such as PoE and UG provide extremely detailed three-dimensional design drawings. Precision machining can process many materials, including steel, iron, aluminum, copper, bronze and some specialty alloys.