Bolt Forging Machine

Bolt Forging Machine

Rainbow’s Bolt Forging Machine is a robust, adaptable equipment for bolt forging processes, transforming metal blanks into components such as bolts, screws, and fasteners. Its cutting-edge technology and meticulous engineering guarantee uniform outcomes, high production speed, and remarkable longevity, making it a perfect choice for manufacturers in diverse sectors.

Types of Bolt Forging Machine

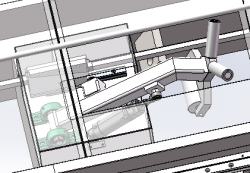

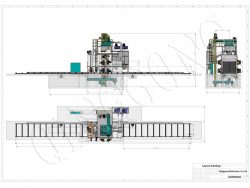

RBF Series 4 Station Bolt Former

This advanced machine is designed for efficient and precise production of bolts, offering four stations for versatile and high-quality bolt manufacturing.

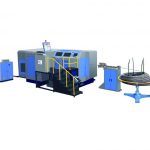

RBF Series 5 Station Bolt Former

This state-of-the-art machine is designed for precise and efficient production of bolts, offering five stations for enhanced versatility and high-quality bolt manufacturing results.

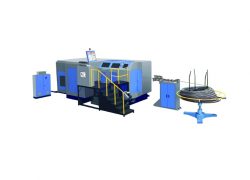

RBF Series 6 Station Bolt Former

Rainbow’s RBF Series 6 Station Bolt Former offers versatile and precise bolt production. With six stations, it ensures high-quality results and seamless operation for fastener manufacturers.

QLBF Series 3 Station Bolt Former

This state-of-the-art machine is designed for efficient and precise production of bolts, offering three stations for versatile and high-quality bolt manufacturing results.

Benefits of Bolt Forging Machine

1

Increased productivity: Bolt forging machine can produce bolts at a much faster rate compared to traditional methods. This leads to higher production capacity and improved efficiency.

2

Improved bolt quality: Bolt forging machines ensure consistent and precise manufacturing, resulting in bolts that meet strict quality standards. This reduces the risk of defects or failures in the bolts, enhancing overall product reliability.

3

Cost savings: By automating the bolt forging process, companies can save on labor costs as fewer operators are required. Additionally, the increased productivity and improved bolt quality contribute to lower production costs in the long run.