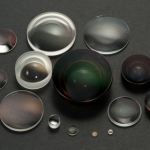

Molding Glass Lens Elements

In the future, molding glass lens elements application will be more popular and mainstream due to its high functional requirements and high stability requirements. As Sunny has nearly 20 years of design and processing experience, we can optimally seek a cost balance between design and processing from the product principle and obtain an optimized solution between performance and cost to the greatest extent.

Compared to glass lens elements, molding glass lens elements have the following advantages:

Optical aberrations, such as spherical aberration, coma aberration, distortion, etc.

Reduce the number of lens elements.

Reduce the size of the lens.

Clear Visual Effect

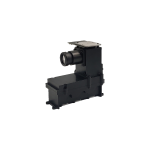

Sunny Automotive is mastering mold design, process, and coating technology with nearly 20 years of design and processing experience. High precision injection machines, coating machines, and testing equipment can ensure high quality lens elements for supply.

The whole process design and processing capacity.

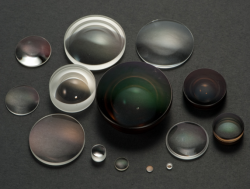

Unique centering and coating technology at the forefront of the industry.

The world’s leading multi-cavity mold processing.

Advanced molding technology without the outer centering(non-edge grinding technology).

Unique molded lens extinction process. Quick and effective response and service.

Competitive cost advantage: in lens design, the combination of mold processing, molding process, and material selection enables the cost of moulded lens elements close to ordinary spherical lens elements.