OEM Precision Machining

Looking for precision machining services that meet your unique needs? Look no further than our OEM precision machining solutions. With state-of-the-art equipment and a team of skilled technicians, we provide custom machining services for a wide range of industries. From prototyping to production, we offer end-to-end solutions that ensure your parts and components are manufactured to the highest standards of quality and precision. Whether you need CNC machining, turning, milling, or drilling, our team can deliver the parts you need on time and within budget. Contact us today to learn more about how we can help you achieve your manufacturing goals.

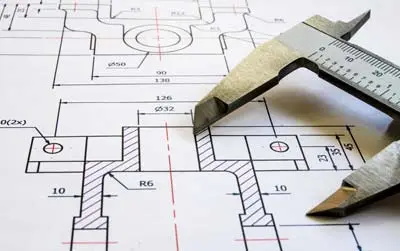

Design Tips for OEM Precision Machined Parts

Design for Ease of Assembly: Take into account the way in which the part will be assembled, including any post-processing. Make sure that all surfaces are accessible and that any fasteners are easy to reach.

Consider Tolerances: Specify a tight tolerance for your parts to ensure the highest accuracy possible. Be aware of the effect of tolerances on the cost and lead time of the part.

Minimize Complexity: Complex parts require more time and skill to machine, so try to design parts with smooth, uniform surfaces and minimal features to reduce costs and lead time.

Use Standard Features: Take advantage of standard features such as threads and tapped holes, as they will often reduce the cost and lead time of machining.

Account for Finishing: If you plan to use a coating or other finishing process, make sure to design the part with this in mind. This may involve leaving extra material on the part to achieve the desired finish.

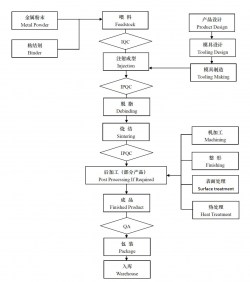

OEM Precision Machining Process

Are you in need of custom parts for your business but don’t have the resources to produce them in-house? OEM precision machining might be the solution you’re looking for. Here’s an overview of the process:

Step 1: Design

The first step in OEM precision machining is designing the part. You can provide us with a 3D model or a detailed drawing of the part you need. We will review the design and provide feedback if necessary.

Step 2: Material Selection

According to your need, we will select the appropriate material for the part. This will depend on the specific requirements of the part, such as its function, durability, and environmental factors.

Step 3: Machining

After selecting the material, we will use a variety of precision machining techniques to create the part. These techniques include CNC milling, turning, grinding, drilling, stamping,deep drawing and so on. The manufacturer will use state-of-the-art equipment to ensure that the part is manufactured to the exact specifications provided in the design.

Step 4: Quality Control

Once the part is machined, it will undergo rigorous quality control checks. This includes dimensional inspections, surface roughness measurements, and material analysis. We will also test the part to ensure that it functions properly and meets all of the necessary standards.

Step 5: Finishing

Finally, the part will be finished according to your specifications. This may include coating, painting, or plating. We will ensure that the finishing process does not compromise the integrity of the part.

In conclusion, OEM precision machining is a complex process that requires expertise, advanced equipment, and strict quality control measures. By outsourcing your custom parts to us, you can ensure that your parts are manufactured to the highest standards and meet all of your requirements.