RAPID HEAT AND COLD HIGH-GLOSS MOLD TEMPERATURE

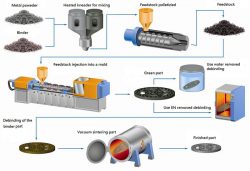

The rapid cooling and rapid heating high-gloss mold temperature machine use the rapid switching between normal temperature water and high-temperature steam to achieve rapid temperature changes in different stages of a molding cycle so that the temperature of the mold can meet the molding temperature requirements to the maximum extent, and give full play to the plastic The molding characteristics of the material. It can completely solve the defects of product welding marks, shrinkage, deformation, surface floating fiber, and silver streaks. And can achieve the effect of high gloss and spray-free.

Specification Of Rapid Heat and Cold High-Gloss Mold Temperature

Standard specifications

SFD-80

SFD-100

SFD-120

SFD-140

Heating medium

Water/Steam

Max. process temperature

℃

185℃

Cooling method

Direct cooling

Heater power

KW

80

100

120

140

Coolant Pump

Motor power

KW

2.2

2.2

2.2

2.2

Max.flowrate

L/Min

166

166

166

166

Controller

Temperature control

PID control

Temp.detection method

JIS K

Water supply pump

motor

KW

2.2

2.2

2.2

2.2

Max.flowrate

L/Min

66

66

66

66

Cooling water inlet-outlet of heating system

DN40

DN40

DN40

DN40

Media import and export

DN40

DN40

DN40

DN40

Electric power source Specification

3P 380V 50HZ

Dimensions (LXWXH)

mm

1500X800X1400

Injection molding machine

~350

Features Of Rapid Heat and Cold High-Gloss Mold Temperature

Able to remove the surface of the product folder waterlines, weld, silver pattern

Can solve the problem of surface shrinkage of plastic products

The product of the high-gloss surface finish can be a mirror

Exempt the product from subsequent fuel injection process, environmental protection, efficient

Shortem the product molding cycle

Variable temperature 180℃~65℃ control

Equipped with communication interface, can undertake future industry 4.0