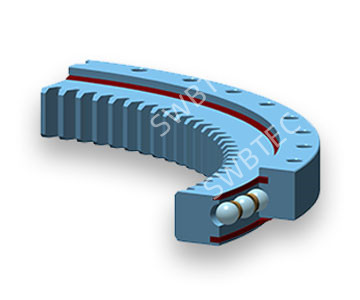

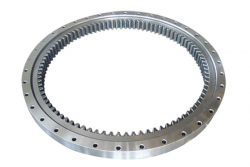

Swbtec Slewing Bearing & Slewing Ring

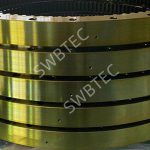

In the process of slewing bearing use, it will endure 3 different direction force, including the axial force Fa, the radial force Fr and the overturning moment M. The combination of the three loads will change as a result of different working ways and different structural types in different practical applications, sometimes it may be bear two loads, sometimes there is just one load. This requires the slewing bearings to have high stability of quality, SWBTEC slew bearing, from raceway hardening to gear hard treatment, we strive to excellence.

Tips For Slew Bearing Selection

For slew bearing selection, we only talk horizontal installation, if is vertical installation, please contact with our engineer before design.

There are single row type slew bearing, crossed roller slew bearing, double row slew bearing and triple row slew bearing, Based on our experience, here is our advice:

when the raceway center diameter is smaller than 1.8 meter, then the single row type slewing bearing is the preferred alternative, when the raceway center diameter is bigger than 1.8 meter, the triple row slew bearing is preferred one. Single row type ball bearing has bigger load capacity than crossed roller type and double row with different diameter ball type slew bearing when there is the same size structure. so we strongly advise to prefer our Q type single row four point contact ball slewing bearing.

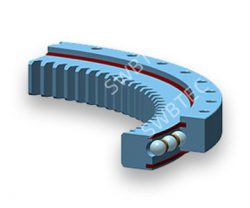

How Does A Slew Ring Work

Change the way of moving from sliding to rolling, reducing frictional resistance, this is how turntable bearing working.

The turntable bearing mainly depend on lubrication and friction to achieve the moving. In the interior, it relies on the mutual friction between the ball and the ring for the purpose of moving. Externally, it relies on the friction between the turntable bearing and other components, like pinion to start to move, It can be used to load large objects, and its own centripetal force requirement is high, which is determined by its working principle, so it need good quality forging steel material that can guarantee the work.

Lubrication is also required as the other indispensable factor, or it will affect the normal operation of the turntable bearing after a long time if there is huge friction force. Therefore, after a period of time, it is very important to greased the bearing which can increase the service life.