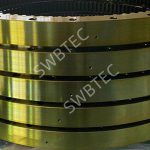

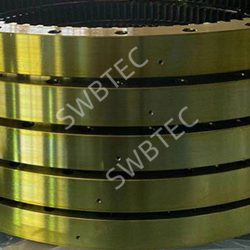

Slewing Bearing With Internal Gear

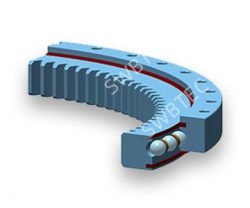

Slewing Bearing With Internal Gear with gear on the internal ring. Gear hardening treatment or not is based on the working conditions. Compared with slewing bearing with external gear, the internal gear will has longer service life when worked in the same environment due to the gear is in the inner ring, as it can make the gear has good dust prevention and the grease oil can be kept for a longer time and more important the internal teeth have lower transmission contact stress and less wear. However, it is inconvenient for installation and fault diagnosis check after some time using due to the size limitation and compact interior space.

Features and Benefits of Slewing Bearing With Internal Gear

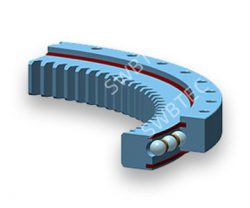

One of the main quality issues we encountered in our aftermarket work a few years ago was raceway noise.

Why is there a raceway noise? We think that the main reason is that the hardness of the raceway is not enough or the quenching depth of the raceway is not enough.After a long period of wear between the steel ball and the raceway, the raceway will be worn out.

Starting from a small area, if the problem become serious, a very loud noise will be emitted. In order to solve this problem, we started from the raceway grinding equipment and the raceway grinding process.

After continuous exploration by engineers and front-line workers, we have successfully mastered and improved the raceway grinding production process, ensuring that there was no noise problems again from that time.