The Modes and Characteristics of PU Continuous Sandwich Panel Production Line

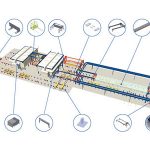

The complete equipment of PU continuous sandwich panel production line is mainly composed of a series of equipment such as uncoiling system, film-coated cutting system, forming machine system, steel plate preheating furnace, high-pressure foaming system, double-track system, double-track heating system, cutting system, horizontal cooling system, palletizing system, packaging system. The forming machine system is the core equipment part.

I. The Production Mode of PU Continuous Sandwich Panel

The production of continuous PU sandwich panel production line is mainly continuous production. At present, the continuous production process is suitable for enterprises with high production requirements.

In the continuous production process, the materials of the sandwich panel are processed together at a high speed. The PU foam continuously sprays between the upper and lower surface materials of the formed sandwich panel that moves at a constant speed, and the polymerization reaction takes place to generate different forms of the sandwich panels. After the sandwich panel is fully formed, the cutting process is carried out according to the expected length without stopping the production line.

II. The Characteristics of PU Continuous Sandwich Panel Production Line

1. The width of the wall panel can be adjusted to meet different requirements of wall widths.

2. The adjustable wall panel rack is welded with integral profiles and the roller shafts on both sides are cantilevers. The single row bearing pedestal adopts the combination mode, which ensures the accuracy and stiffness of the bearings. The single row bearing pedestal is mounted on the spherical guide, and the specification can be easily adjusted by adjusting the screw rod.

3. The round screw die and the roll shaft of the rollforming equipment are made of high-quality carbon structural steel. After quenching and tempering treatment as well as CNC finish machining, the surface is plated with hard chrome, and the comprehensive structural performance ratio is good, which ensures the plate to form stably, smoothly and normally.

4. The bearing pedestal of roof sheathing forming machine adopts independent square strip assembly structure. With surface galvanization treatment, the appearance is beautiful, the rigidity is high, and the structure is reasonable.

5. The main drive reduction motor, other reduction motors, as well as important parts and components of the roll forming machine adopt the equipment produced by well-known enterprises, thus effectively ensuring the overall performance of the PU continuous sandwich panel production line.

Buy China sandwich panel production line from Jinggong, your reliable partner!