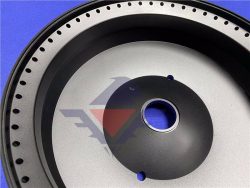

Globe Valve

UTMOST, as one of the most professional globe valve suppliers in China, sticks to providing high performance pneumatic actuator globe valves of different sizes and materials. A full selection of globe valve materials including carbon steel, stainless steel, heat resisting steel, alloy steel. Inconel, Monel, and Hastelloy alloy are on offer; actuators are both on electric and pneumatic options; And the inside nominal diameter ranges between DN15(l/2″) and DN1200(48″), with nominal pressure from PN16(ANSI150) to PN400(ANSI2500), connection type included NPT/FF/RF/RTJ. If you want to customize your group valve, please contact us for more detailed globe valve cost and customization services.

Globe Valve for Sale

A globe valve is a valve in which the closing member (valve flap) moves along the centerline of the valve seat. According to this form of movement of the valve flap, the change of different types of globe valves seat opening is proportional to the stroke of the valve flap. Due to the relatively short opening or closing stroke of the valve stem and the very reliable cut-off function of this type of automated globe valve, and because the change of the valve seat opening is in a king proportional relationship with the stroke of the valve flap, it is ideal for the regulation of the flow. Therefore, this type of valve is ideal for use as a cut-off or regulating and throttling valve. UTMOS is a high pressure globe valves manufacturer and valve factory in China that offers various types of globe valves for sale. Contact us to get the globe valve price now.

Globe Valve Characteristics

Globe valve is suitable for cutting off or connecting pipeline media in various working conditions in petroleum, chemical, pharmaceutical, fertilizer, and electric power industries with nominal pressure PN1.6~16.0MPa and working temperature ≤600°℃. Its main structural features are as follows:

The product structure is reasonable, has reliable sealing, excellent globe valve operation performance, beautiful shape.

Co-based hard alloy is overlaid on the sealing surface, with good wear resistance, corrosion resistance, and anti-scuffing performance, and long service life.

The stem is tempered and surface nitride treated, with good corrosion resistance and anti-scuffing.

The nominal pressure 225.0MPa(Class1500) middle cavity adopts a self-tightening seal type structure, the sealing performance is enhanced with the increase of pressure to ensure the sealing performance.

The valve globe type is equipped with an inverted sealing structure for reliable sealing.

The globe valve material of parts and the globe valve sizes of flange and butt welding end can be reasonably matched according to the actual working condition or user requirements to meet various engineering needs.

Globe Valve Datas

Materials of Globe Valve Main Parts

No.

Parts Name

Material

Stainless Steel

Cast Steel

1

Body

A351-CF8

A216-WCB

2

Disc

A182-F304

2Cr13

3

stem

A182-F304

A182-6a

4

Disc cover

A182-F304

2Cr13

5

Spiral wound gasket

PTHE

graphite+304

6

The seal seat

F304

2Cr13

7

Valve cover

A351-CF8

A216-WCB

8

Bolt

A193-B8

A193-B7

9

nut

A194-8

A194-2H

10

Packing

PTFE

graphite

11

Press kit packing

CF8

2Cr13

12

Packing plate

CF8

A216-WCB

13

nut

A194-8

A194-2H

14

Pin

410

35

15

Bolt

A193-B7

A193-B7

16

stem nut

ZCuA110Fe3

ZCuA110Fe3

17

Screw

410

A105

18

Handwheel

QT400

QT400

19

Nameplate

L2

L2

20

nut

B8

A194-2H

21

Washer

410

Q235A

CLASS150Lb

NPS

1/2

3/4

1

11/4

11/2

2

21/2

3

4

5

6

8

10

12

DN

15

20

25

32

40

50

65

80

100

125

150

200

250

300

RF

108

117

127

140

165

203

216

241

292

356

406

495

622

698

RTJ

119

130

140

152

178

216

229

254

305

369

419

508

635

711

BW

108

117

127

140

165

203

216

241

292

356

406

495

622

698

d

13

19

25

32

38

51

64

276

102

127

152

203

254

305

H

182

193

217

235

258

330

360

390

445

480

520

600

773

880

H1

–

–

–

–

–

–

–

–

–

–

556

658

805

955

W

100

100

100

135

135

200

250

280

300

350

350

400

450

500

W1

–

–

–

–

–

–

–

–

–

–

310

310

460

460

H.W

3

4

5

8

9

19

27

36

53

75

94

148

242

438

G.O

–

–

–

–

–

–

–

–

–

–

126

180

291

480