Screening in Mining

Generally speaking, mineral processing refers to the processing of ores and minerals, such as gold, coal, nickel, aluminum, oil sands, phosphate, potash, copper, iron ore, and so on.The process is to separate valuable minerals from waste materials. Usually, in mineral processing, minerals are recovered from ore through a variety of operations, including crushing, classification, concentration, and dewatering.

Different Usages of Mining Screen in Mining Industry

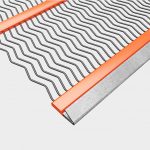

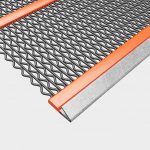

Mineral processing is one of the most important aspects of the entire mining operation, and screening and classification of mined materials plays a big part in mineral processing. Most of the mined materials, from hard rock ores to solid-fuel minerals, such as coal, oil shale, and industrial minerals, undergo some size reduction and/or other beneficiation processes.

Advantages of Screening in Mining Industry

Both mining and mineral processing industry rely heavily on screening because it effectively separate important minerals from mined materials.

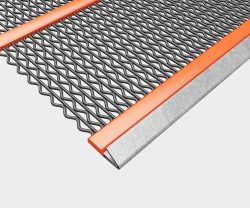

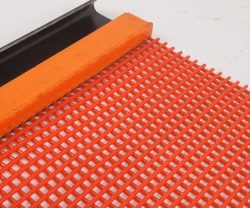

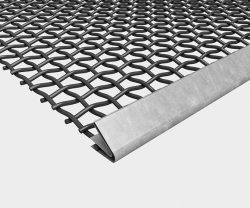

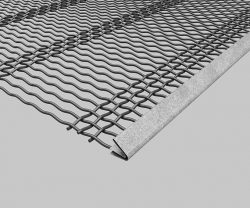

Using Anpeng tailored high-quality screening equipment effectively filter out minerals with desired particle sizes or characteristics.

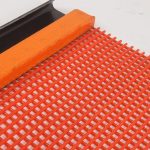

Consider using Anpeng water proof PU-Mesh during dewatering for extended wearlife and maximized output.