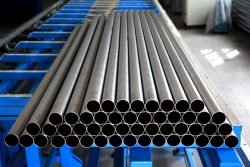

TITANIUM FOR 3D PRINTING

Titanium has found increasing applications in the field of 3D printing. It is an ideal choice for 3D printing because of its high strength, biocompatibility, corrosion resistance, and lightweight properties. The following are some critical applications of titanium in 3D printing:

AEROSPACE:

The aerospace industry relies heavily on 3D-printed titanium parts. 3D-printed titanium parts are crucial for the production of aircraft engines, landing gears, and other structural components. The metal’s high strength-to-weight ratio makes it suitable for applications where lightweight is necessary.

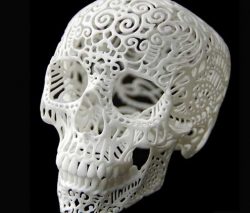

MEDICAL:

The use of titanium in 3D printing has revolutionized the medical industry, enabling the manufacture of implants with tailored designs. The biocompatibility of titanium makes it the ideal material for manufacturing prosthetics such as cranial implants and dental implants. The metal’s ability to fuse with the body’s natural bone contributes significantly to reduce the body’s rejection of medical implants.

INDUSTRIAL:

Industrial applications for titanium 3D printing includes the production of titanium parts for pumps, control valves, and compressors, where high hardness and corrosion resistance play a significant role in the successful operation of equipment.

AUTOMOTIVE:

The automotive industry is another area where titanium finds immense use in 3D printing. The use of 3D-printed titanium components enables the production of lightweight vehicles, reducing the impact of the vehicles’ fuel consumption on the environment.

In conclusion, the flexibility and customization offered by 3D printing processes ensures that titanium parts can be designed and produced with different geometries and intricate designs with utmost precision. The metal’s unique properties make it ideal for several crucial applications in various industries such as the aerospace, medical, and industrial. As 3D printing continuously evolves, the continued use of titanium in complex manufacturing process will enable the production of better products in industries that require efficient strength, corrosion-resistance, biocompatibility and low weight.