Wind Tower Bending Machine

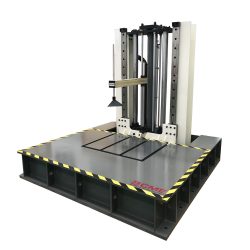

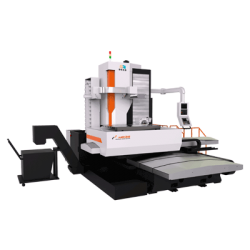

CNC variable geometry three roll plate rolling machine adopts the structure of oil cylinder down. The upper work roll of the wind tower bending machine is the main driving roll: the upper roll is driven by the hydraulic motor (one motor) through the planetary reducer, and the two lower rolls are driven by the hydraulic motor planetary reducer respectively. The lifting of the upper roller is realized by a hydraulic cylinder, the lifting displacement is controlled by computer, automatic leveling, screen display, and synchronous precision ± 0.2mm.

The horizontal position of the two lower rollers can be adjusted independently, the horizontal movement adopts hydraulic transmission, and the center distance can be adjusted; The rolling cone stop is installed on the bearing seat of the lower roll on the overturning side to slow down the small end of the sector plate and realize the cone rolling in a certain range; General cone angle 30 °, 50% of full load. The tail part of the upper roll is equipped with a balance mechanism, which can easily unload the rolled workpiece and cylinder. The wind tower bending machine is equipped with a fixed console and a remote control button box, which is convenient for workers to use. And the wind tower bending machine is equipped with a safety interlock device to make the operation safer. The machine is simple to operate, easy to maintain, high rolling accuracy is an advanced and practical large plate rolling equipment.

https://www.ezhonggroup.com/products/wind-tower-bending-machine/