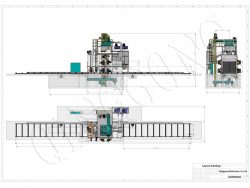

Coil Sheet Laser Cutting Machine

The coil sheet laser cutting system combines with the de-coiling system, leveling system and laser cutting system. It’s suitable to process the multi shape of products, can realize customized manufacturing. Compared with traditional coil processing lines, our sheet metal coil line machine laser cutting system with features of high precision, high productivity, less cost on labors, and stable operation. which is suitable for cutting metal coils, such as stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, galvanized steel, copper, etc. We also provide sheet metal slitting machine for sale. Contact us for further information!

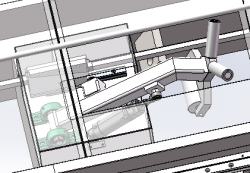

Decoiler,hydraulic lifting, all servo support, and remote control.

Levelling, which is to straighten from coil sheet.

Manufacturing steps: Fiber Laser cutting or Punching Or shearing or folding.

Post-processing, such as robot handling to stack automatically or welding etc.

Coil Fed Laser Cutting Machine Features

Fully-automation can realize to process from the raw metal coils to the final profiles, no need a numeral labors to handle different devices and a few cycles of loading and unloading, There is no need to change the dies, and no waste of time or labors, can realize the higher flexibility manufacturing faster react to the customer’s needs and rapid react to the market changes.

Higher productivity, there is no waste of labor landing and blanking compared with traditional line. Only one worker can handle the whole lines. It is stable operation, no need to change the dies, less operation.

High precision and accuracy, the system apply with the servo feeding system and solid fiber laser technology, which make sure the precision.

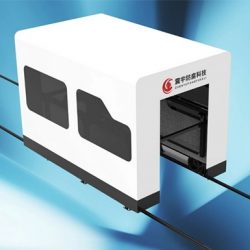

Coil Laser Cutting Machine Parameter Details

Number

Item

Specification

Laser cutting station

1

Laser source power

1500W

2

Working area

3000mm×1500mm

3

X、Y axis positioning accuracy

±0.05mm/m

4

X、Y axis repositioning accuracy

±0.03mm

5

Max running speed

120m/min

6

Max acceleration

1.2G

7

Workbench maximum load weight

800kg

8

Station weight

6.5T

9

Station size(length*width*height)

6m×2.92m×2.0mm

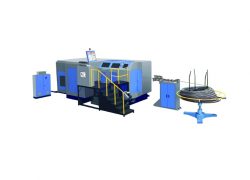

De-coiling station

10

De-coiling width/capacity

300-1250mm/10T

11

Decoil landing capacity

10T

Levelling station

14

Levelling rollers

Up 5/down 4

15

Output speed

16m/min