3D PRINTING & MOLD IS THE FUTURE OF LOW-VOLUME INJECTION MOLDING PRODUCTION

3D PRINTING & MOLD IS THE FUTURE OF LOW-VOLUME INJECTION MOLDING PRODUCTION

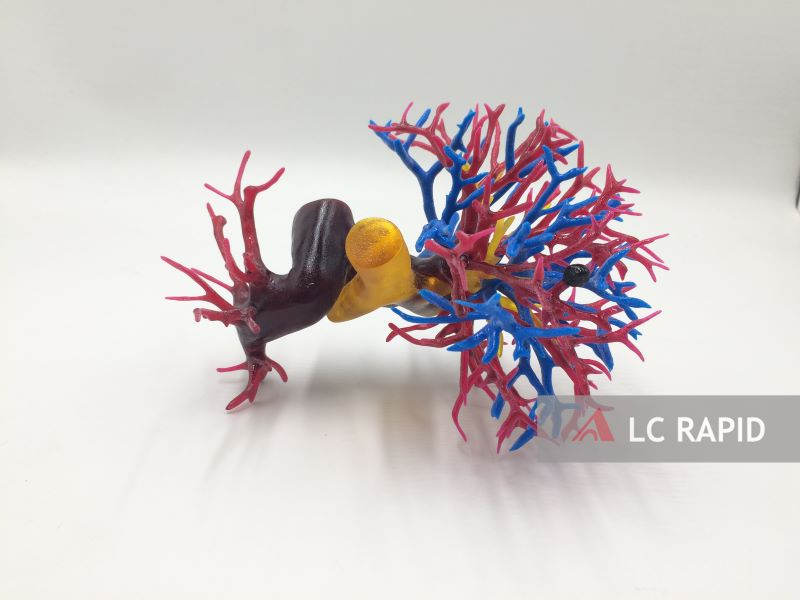

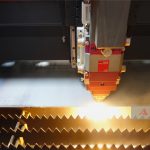

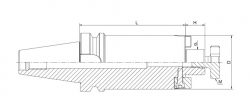

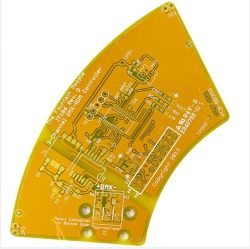

In the past, the molds used for injection molding were usually made of steel or aluminum, and used reducing material manufacturing technology, such as CNC machine tools. But recently, more companies have tried to use more advanced 3D printing processes to simplify the mold making process. This technology is very suitable for low volume injection molding.

1.Why do we need to perform low-volume injection molding?

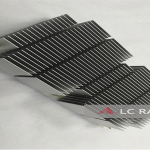

At the moment when the customer market is changing, a new product is mass-produced without market verification, which is extremely risky. The significance of low-volume injection molding is: first small-scale production to verify market demand, and then mass production under the condition of market approval, this method is obviously more secure. For example, when a new type of Apple computer heat sink is developed without market verification, a low-volume injection molding process can be performed first, and then a large number of them can be put into the market after testing.

2.Low-volume injection molding process

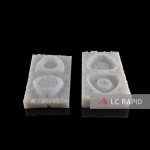

In the low-volume injection molding process, 3Dprinting and manufacturing may be a better choice. Unlike the vacuum compound mold, the injection mold can be used repeatedly more than 100,000 times, so usually only one mold is needed. The low-volume injection molding process is as follows:

First, we need to make a mold, usually using 3D printing technology to make it. After the mold is made, the granular injection material is turned into a liquid by hot melting, and then the liquid is compressed and injected into the cavity of the mold, solidified quickly and then ejected. The production time of each part depends on its size and the materials used. From small and simple to large and complex designs, the required unit production time may range from a few seconds to two minutes.

3.The cost of low-volume injection molding

The molds printed by 3D printing technology make the process of low-volume injection molding cheaper. Compared with other processes, the unit price is significantly lower, and prototypes and samples can be manufactured faster, or low-volume production at reasonable cost.