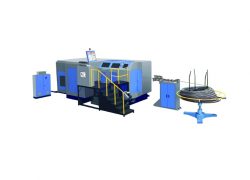

RBF Series 6 Station Bolt Former

RBF Series 6 Station Bolt Former

The RBF Series 6 Station Bolt Former is an advanced piece of equipment designed for the efficient and precise production of bolts. With its six stations, it offers a comprehensive bolt manufacturing process including heading, threading, and trimming. This automatic nut bolt manufacturing machine ensures high productivity, accuracy, and versatility, making it suitable for manufacturers requiring large-scale bolt production with a wide range of specifications. The RBF Series 6 Station Bolt Former is an excellent choice for achieving optimum efficiency and quality in bolt manufacturing operations.

Specifications of RBF Series 6 Station Bolt Former

Main Technical Data of RBF Series 6-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF 46S

RBF -66S

RBF 86S

RBF-106S

RBF-136S

RBF-136L

Forging station

No.

6

6

6

6

6

6

Forging force

Kgs

24,000

50,000

90,000

110,000

140,000

140,000

Max cut-off dia.

mm

Ф7

Ф10

Ф13

Ф16

Ф18

Ф18

Max cut-off length

mm

66

100

100

133

140

185

Speed Range

pcs/min

125-210

110-180

90-150

85-140

65-105

60-100

P.K.O Stroke

mm

10

26

26

26

26

30

K.O Stroke

mm .

51

85

85

110

110

160

Main slide stroke

mm

114

140

140

190

206

270

Main motor

kw

7.5

15

22

30

45

45

Cut-off-die size

mm

Ф24*35L

Ф35*45L

Ф42*60L

Ф52*75L

Ф58*80L

Ф58*80L

Punch die size

mm

Ф31*65L

Ф40*90L

Ф45*115L

Ф53*115L

Ф60*130L

Ф60*130L

Main die size

mm

Ф38*85L

Ф50*120L

Ф60*120L

Ф75*135L

Ф94*135L

Ф94*190L

Die pitch

mm

46

64

80

94

110

110

Machine Weight(Approx)

Kgs

9,000

16,000

20,000

24,000

31 ,000

35,000

Normal bolt size

mm

2-4

3-6

5-8

6-10

8-12.7

8-12.7

Shank length of blank

mm

6-50

15-75

15-77

15-102

20-100

20-150

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won’t be given then.

The products’ most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

At Rainbow, we understand the dynamic nature of manufacturing processes. Our commitment to innovation and reliability shines through in every aspect of our fastener equipment. Experience precision and efficiency with our state-of-the-art Nut Bolt Manufacturing Machine. Trust Rainbow for excellence in manufacturing technology.

Main Technical Data of RBF Series 6-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-136LL

RBF-166S

RBF-206S

RBF-206L

RBF-256S

RBF-276S

Forging station

No.

6

6

6

6

6

6

Forging force

Kgs

140,000

230,000

390,000

390,000

500,000

730,000

Max cut-off dia.

mm

Ф18

Ф23

Ф30

Ф30

Ф34

Ф41

Max cut-off length

mm

240

190

195

240

320

320

Speed Range

pcs/ min

55-90

55-95

50-80

40-70

40-60

30-50

P.K.O Stroke

mm

40

35

46

45

50

50

K.O Stroke

mm

210

165

180

220

280

280

Main slide stroke

mm

320

280

280

346

446

450

Main motor

kw

45

75

90

90

132

200

Cut-off-die size

mm

Ф58*80L

Ф74*105L

Ф94*130L

Ф94*130L

Ф109*150L

Ф129*180L

Punch die size

mm

Ф60*130L

Ф75*185L

Ф90*215L

Ф90*215L

Ф120*270L

Ф180*270L

Main die size

mm

Ф94*240L

Ф108*200L

Ф125*200L

Ф125*240L

Ф148*300L

Ф178*300L

Die pitch

mm

110

129

140

140

160

190

Machine Weight(Approx)

Kgs

42,000

56,000

80,000

80,000

135,000

170,000

Normal bolt size

mm

8-12.7

10-16

12-20

12-20

16-25.5

20-28.5

Shank length of blank

mm

20-200

25-152

25- 160

25-200

50-250

50-250

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won’t be given then.

The products’ most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

For further details and to explore how Rainbow nut and bolt manufacturing machine can enhance your production capabilities, please reach out to us.

Features of RBF Series 6 Station Bolt Former

01

Coordinated Clipping Table Movement

To achieve synchronized movements, a j-pint intermediate shaft drives both the reciprocating movement of the clipping table and the opening/closing of the clips.

02

Adjustable Rear Knock-Out Mechanism

Rear knock-out mechanisms can be individually and separately adjusted for different stations. The last station is. All models’ dead-point positions remain the same prior to being removed. Rear knock-out threaded pipe adjustment mechanisms can be added to some models using a hand wheel or a CNC machine.

03

Overload Protection

RBF serial model’s punch knock-out mechanism. Punch knockout occurs at the same time as the machine slider’s back movement. The work piece remains in the mold after being moulded before being knocked out by a rear knock-out mechanism. It avoids getting distracted by the punch and being malformed. The placements of different front knock-out stations can be individually changed. All of the front lead-out mechanisms feature provisions to protect against knock-out forces exceeding loads.

04

Quiet and Efficient Electric Feeding Mechanism

Is the feeding mechanism electric, During the return stroke, the air cylinder has the ability to lift the pawl and detach it from the ratchet wheel. In addition to removing friction and noise, this bolt forging machine also stops the ratchet wheel from turning in the other direction.