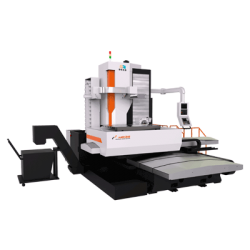

CNC MILLING

We have 30 CNC milling machines, which provide the processing capacity of 100,000 pieces per year, which can ensure that all surfaces are processed in place. We have high-precision (± 0.005) CNC milling, and the milling range is from 1mm to 1500mm. Surface, groove, taper surface, hole, special-shaped surface and other processing are the main processing scope of CNC milling services. Our enterprise has realized the networked control of multiple machine tools to realize the synchronous implementation and monitoring of the production process.

What is CNC Milling?

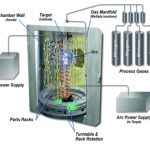

CNC milling is an indispensable process in modern machining. The process differs from turning is that turning is the high-speed rotation of the machined part, and the tool moves slowly along the x.y.z direction on the tool holder to cut off the material. CNC milling process adopts that the material does not move, the tool rotates at high speed on the tool holder and moves slowly along with the three directions of x.y.z to cut off the material. At the same time, NC milling machine tools are generally equipped with a tool magazine, which can automatically select the tool through the program to realize the whole process of unmanned operation, and stabilize the quality. CNC milling turning improves efficiency, and reduce the labor cost and man-made impact on quality.

What is the Difference Between Milling and CNC Milling?

With the progress of modern society, processing and manufacturing technology is also making continuous progress. The biggest change of milling processing is the progress from ordinary milling to CNC milling. The biggest difference between ordinary milling and CNC milling lies in the degree of automation and efficiency of machine control. 90% of ordinary milling operations need to be completed manually, including CNC material selection, placement, angle setting, tool selection, feed amount, feed direction, etc., including the final product taking and placing. Basically, only 10% of the work of CNC milling needs to be completed manually. The manual operation content only includes writing and debugging programs, loading and unloading materials, and checking the operation in the middle. Connecting multiple machines can greatly reduce the demand for personnel and improve efficiency.

Applications of CNC Turning and Milling

CNC milling is more applied to complex surfaces, step surfaces, helical surfaces (threads), inclined surfaces (taper surfaces), chamfers, grooves (keyways, grooves, T-grooves, etc.) with complex shapes, and complete processing of parts without replacement.

In part processing of CNC milling working, automatic tool change can greatly improve efficiency. Because of its flexible processing characteristics, NC milling is the absolute main processing technology in the whole processing industry.

Advantages of CNC Milling

01

CNC milling is especially suitable for parts with strong adaptability to materials and difficult to control size or parts with particularly complex contour shapes.

02

CNC milling operation can process parts that are difficult or impossible to be processed by ordinary turn-milling machine tools, such as linear surfaces, circular arc surfaces, etc.

03

After one clamping and positioning, the precision CNC milling machine can complete the processing of multiple processing procedures and multi-faceted and multi-type processes, such as milling, chamfering, milling round hole, drilling, reaming, reaming, boring, thread milling, and so on.

04

The equipment has a high degree of automation, especially the equipment with tool magazines and automatic tool changes. Reduce labor intensity and repeated the tooling process. When the quality needs to be checked, the processing can be stopped at any time, and the continuous production can not be adjusted after the inspection.

CNC milling is an indispensable process in modern machining. The process differs from turning is that turning is the high-speed rotation of the machined part, and the tool moves slowly along the x.y.z direction on the tool holder to cut off the material. CNC milling process adopts that the material does not move, the tool rotates at high speed on the tool holder and moves slowly along with the three directions of x.y.z to cut off the material. At the same time, NC milling machine tools are generally equipped with a tool magazine, which can automatically select the tool through the program to realize the whole process of unmanned operation, and stabilize the quality. CNC milling turning improves efficiency, and reduce the labor cost and man-made impact on quality.