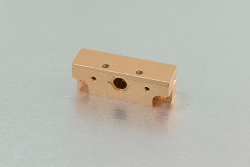

HIGH PRECISION PARTS INDUSTRIES

We pride ourselves on providing top-quality custom solutions for a variety of industries including automotive, medical, aerospace, thermostat, household electrical appliance and heating markets.

Our expert team works closely with clients throughout the entire manufacturing process to engineer precision parts, components, assemblies, and motion control solutions that exceed expectations. With a global presence and a commitment to excellence, we are dedicated to helping our clients “engineer possible” and achieve success in their respective industries.

Different High Precision Parts Industries

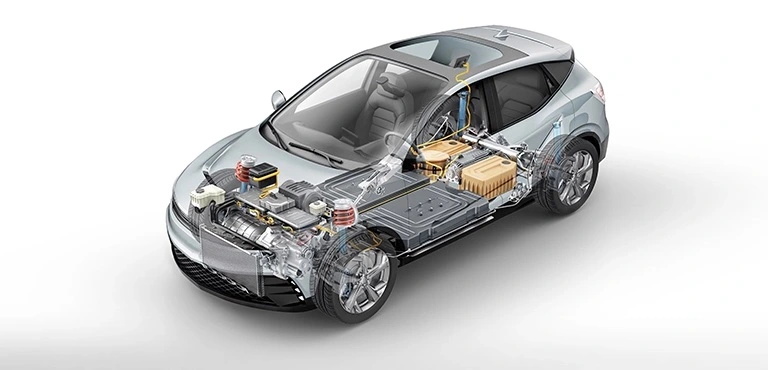

New Energy Parts

Get top-quality high precision metal parts for new energy applications. Our components meet the most demanding specifications for reliable performance in challenging environments.

Electrode Slice

Tape and Reel PCB Nut

Battery Post

Tape and Reel PCB Washer

Lug Tabs

Battery Case/Battery Housing

The Benefits of Automation for High Precision Parts

INCREASED EFFICIENCY

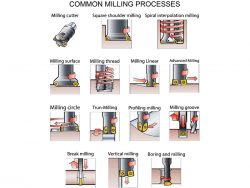

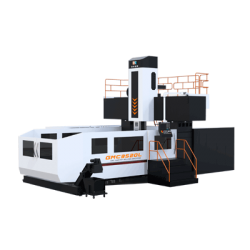

Automation in high precision industrial cnc parts industries can significantly increase efficiency by reducing the time required to produce complex parts. Robots can work around the clock, without the need for breaks or rest, leading to increased productivity. This translates to faster turnaround times, lower lead times, and increased customer satisfaction.

IMPROVED ACCURACY

Automation can improve the accuracy of the parts produced. With high precision measurement systems and advanced software, robots can create parts with consistent quality, reducing the risk of human error. This not only increases the overall quality of the parts produced but also reduces the risk of costly defects.

LOWER COSTS

Automation can help reduce costs in several ways. With robots doing the work, there is less need for human labor, reducing labor costs. Automation also reduces material waste by minimizing the number of parts that need to be scrapped due to defects. Furthermore, automated processes can optimize the use of raw materials, reducing material usage and overall costs.

Exploring the Impact of 3D Printing on High Precision Parts

In recent years, 3D printing has emerged as a game-changer in the manufacturing industry. With its ability to produce intricate and complex parts with high precision, it has disrupted traditional manufacturing processes and opened up new possibilities for industries that rely on high precision parts.

The impact of 3D printing on the high precision parts industries is significant. It has enabled faster prototyping and production of parts, reduced costs associated with traditional manufacturing processes, and improved the overall quality and performance of the parts produced.

Moreover, 3D printing has also facilitated the creation of new designs that were previously impossible to manufacture. This has led to the development of new products and technologies that were not feasible with traditional manufacturing methods.

However, despite the numerous benefits of 3D printing, there are still challenges that need to be addressed. One major challenge is the lack of standardization and quality control measures for 3D printed parts. As a result, there is a need for the development of industry standards to ensure the quality and consistency of 3D printed parts.=

In conclusion, the impact of 3D printing on the high precision parts industries is undeniable. As the technology continues to evolve, it is expected to play an even greater role in the manufacturing industry, revolutionizing the way we design and produce high precision parts.