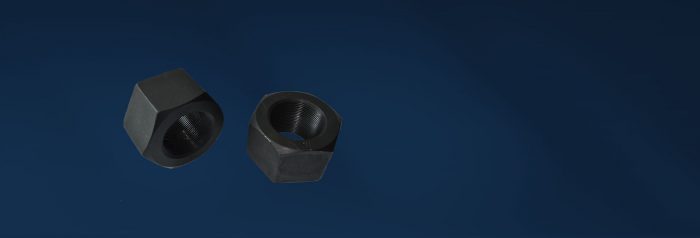

Heavy Hex Nuts

DATIAN (DT) Fastener is famous for producing quality heavy hex nuts. We, one of the professional heavy hex nut manufacturers, have a in house full line heat treatment machine used to improve the hardness and mechanical properties of heavy hexagonal nuts in order to serve different high requirement areas. The heavy duty hex nuts standard we listed below are most ASTM A194/A563 and ANSI/ASME B18.2.2 heavy hex nuts. Compare to finished hex nuts, the heavy hex nut carry higher grade and slightly wider and thicker diameters to meet the greater length of thread engagement and better resistance to stretching or widening. Contact DT Fastener, a professional nuts and bolts manufacturing company, for more info now!

Heavy Hex vs Hex

The first thing to declare is that both heavy hex nuts and finished hex nuts belong to the hexagon nut classification. Simply put, the difference between them is that heavy hex nuts have larger widths across the flats and heights of the same nominal size. This gives heavy hex nuts higher load retention and tensile strength. This also explains why heavy hex nuts can be heat treated to achieve higher hardness.

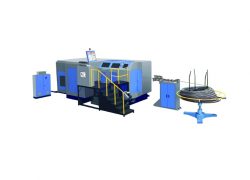

There are two production processes for Datian Fastener’s Heavy hexagon nuts – cold heading and hot heading.

The cold heading machine of Datian Fastener has the ability to form the nut from raw material to finished product at one time. Our cold heading machine integrates the rolling thread machine and the cold heading machine to maximize efficiency, ensure the customer’s delivery requirements, and minimize the labor cost, which makes the price of our heavy hexagonal nut competitive all over the world.

Hot forming: Generally, hot forming is selected for larger fasteners, and the diameter range are generally 1”~4”~(M30~M100) or even larger. The material used in the hot heading machine is generally round steel, without cold drawing and pickling. The production step is to cut the material first, and then upsetting by the punch. The surface of the semi-finished product of red punching is rougher than that of cold heading. After tapping, the two sides of the nut are chamfered with a CNC machine, and finally it is completed after heat treatment and surface treatment.

Cold heading and hot heading are roughly divided into the following steps: Cold heading: wire drawing – cold heading – (heat treatment) – tapping – surface treatment

Hot forming: cutting material – red punching – chamfering – turning – (heat treatment) – tapping – surface treatment Or cutting material – upsetting ball – annealing, phosphating – forming – punching – (heat treatment) – tapping – surface treatment.