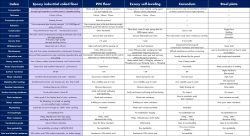

Industrial Flooring

Industrial flooring is more resistant to the corrosion of dozens of chemical substances such as strong acids, alkalis, and oils than PVC flooring, while also being more wear-resistant, pressure resistant, and impact resistant. Industrial flooring is suitable for electronic and microelectronic industries that require high cleanliness, aesthetics, dust-free, and sterility, pharmaceutical industries that implement GMP standards, precision instruments, aerospace, and other fields. It has the advantages of seamless, solid texture, waterproof, moisture-proof, and anti-skid functions, convenient maintenance, and low maintenance costs. The difference from industrial floor tile flooring is that in addition to having the high strength, wear resistance, and pressure resistance of floor tiles, it also has a certain degree of elasticity and flexibility, lighter sound noise, better foot feel, and certain functions of warmth, sound insulation, and dust prevention, which cannot be met by floor tile flooring.

Compared with floor paint, industrial flooring has more obvious advantages, such as longer service life and better comfort. Due to the Thermal expansion of the ground surface, the floor paint is more likely to be damaged, dust is easily generated, and maintenance is frequent. And after repair, the color difference is different and the sensory perception is not ideal.

Industrial Flooring Types

Epoxy Polymer Industrial Flooring

The polymer industrial floor can achieve an ultra-high wear resistance of 21500 revolutions (tested with 180 grit sandpaper), and can be repaired and refurbished through polishing after damaging scratches are generated. The thickness of the wear-resistant layer on the floor surface layer is as high as 0.7-1.2 mm, and the wear-resistant layer is produced from pure material. There is no dust and no discoloration when polishing the floor, Polishing, waxing, or roller coating with water-based polyurethane can rejuvenate the old ground.

Epoxy Flooring Paint

Our products include solvent-free and water-based epoxy resin floor coatings, polyurethane floor coatings, ultra wear-resistant polyurethane covering materials, solvent-free colored sand self-leveling materials, and elastic acrylic floor materials. Representative inorganic products include emery wear-resistant aggregates, special cement-based self-leveling materials, rapid repair mortar materials, and inorganic grinding stone matching materials. This product has good permeability and sealing properties to concrete, improves the hardness of the base surface, and provides good adhesion, with good economy. Epoxy floor paint has the advantages of rich products, excellent quality, convenient construction, low price, and perfect after-sales service.

VIEW MORE

Epoxy Flooring Paint

01 02

Epoxy Polymer Industrial Flooring

Epoxy Flooring Paint

Sustainable And Eco-Friendly Options for Industrial Flooring

Sustainable development and meeting the requirements of environmental protection:

Cost reduction and efficiency enhancement: Epoxy polymer industrial flooring is cheap in price, with a service life of 8-10 years, and there is basically no need for high cost maintenance. Based on the two to three year renovation or maintenance of industrial flooring used in other categories, the product has a higher cost-effectiveness.

The product is easy to lay and can be installed without stopping production. At the same time, it can be loaded and used in one day, saving decoration time and costs for enterprises.

The product has good detection performance, does not contain harmful substances, meets the requirements of high-quality ambient air, and is energy-saving and emission reducing.

Maintenance And Cleaning of Industrial Flooring

Maintenance And Cleaning:

After 8 hours of paving, it can be pedestrian and loaded after 24 hours.

During use, sharp objects should be avoided from scratching the ground.

During use, people and objects should try to avoid bringing in coarse and hard gravel, and if there is any, it should be removed in a timely manner.

Regular Sweeping: Regularly sweep the floor to remove dust, dirt, and debris. This can prevent scratches and damage to the floor surface.

Use Appropriate Cleaning Solutions: Use a cleaning solution suitable for the type of industrial flooring. Avoid harsh chemicals that can damage the floor. Always follow the manufacturer’s instructions.

Regular Mopping: Mop the floor regularly to remove any stains or spills. For larger industrial spaces, an automatic floor scrubber may be more efficient.

1

When welding or installing heavy equipment in the paving area, necessary protective measures should be taken for the ground.

2

Adhering to daily maintenance and cleaning, keeping the workshop or work environment clean, is also beneficial for extending the service life of the floor panel and reducing the repair rate.

Quality Control Measures in Industrial Flooring Manufacturing Processes

1. Raw Material Inspection: The first step in quality control is to inspect the raw materials used in the manufacturing process. This includes checking the quality of cement, aggregates, and other materials to ensure they meet the required standards.

2. Process Control: This involves monitoring the manufacturing process to ensure that it is carried out correctly. This includes checking the mixing of materials, the pouring of the concrete, and the curing process.

3. Testing: Various tests are carried out on the finished product to ensure it meets the required standards. This includes strength tests, slip resistance tests, and durability tests.

4. Inspection: The finished product is inspected for any defects or irregularities. This includes checking for cracks, uneven surfaces, and other issues that could affect the performance of the floor.

5. Documentation: All quality control measures are documented for future reference. This includes recording the results of tests and inspections, as well as any actions taken to correct issues.