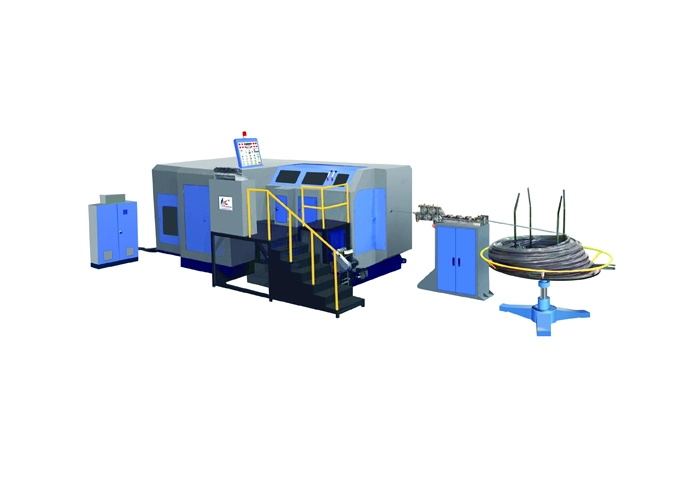

RBF Series 5 Station Bolt Former

RBF Series 5 Station Bolt Former

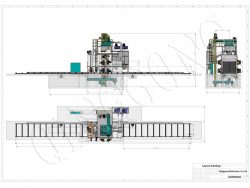

The RBF Series 5 Station Bolt Former is a specialized equipment used for the efficient and precise production of bolts. With its 5 stations, it offers multiple operations such as heading, threading, and trimming, allowing for a complete bolt manufacturing process in a single machine. This machine is designed for high productivity and accuracy, making it an ideal choice for manufacturers in need of large-scale bolt production.

Specifications of RBF Series 5 Station Bolt Former

Main Technical Data of RBF Series 5-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF- 65S

RBF 85S

RBF-105S

RBF-135L

Forging station

No.

5

5

5

5

Forging force

Kgs

43,000

85,000

98,000

145,000

Max cut-off dia.

mm

Ф8

Ф10

Ф12

Ф15

Max cut-off length

mm

95

100

133

185

Speed Range

pcs /min

120-200

95-160

90-150

60-105

P.K.O Stroke

mm

15

26

20

30

K.O Stroke

mm

80

85

110

160

Main slide stroke

mm

136

140

190

270

Main motor

kw

15

22

30

37

Cut-off-die size

mm

Ф30*45L

Ф35*62L

Ф45*59L

Ф63*69L

Punch die size

mm

Ф40*90L

Ф45*115L

Ф53*115L

Ф60*130L

Main die size

mm

Ф50*110L

Ф60*120L

Ф75*135L

Ф86*190L

Die pitch

mm

60

80

94

110

Machine Weight(Approx)

Kgs

11T

17,000

20T

32,000

Normal bolt size

mm

3-6

5-8

6-10

8-12.7

Shank length of blank

mm

10-75

15-75

15-100

20-150

Mechanical Dimensions(cm)

cm

350*220*170

420*250*190

455*275*230

560*300*225

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won’t be given then.

The products’ most applicable production speed is decided by the product shape, size and materia.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Main Technical Data of RBF Series 5-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-165S

RBF-205L

RBF-255L

RBF-255LL

RBF-305L

Forging station

No.

5

5

5

5

5

Forging force

Kgs

236,000

380,000

480,000

480,000

600,000

Max cut-off dia.

mm

Ф18

Ф23

Ф30

Ф32

Ф36

Max cut-off length

mm

190

240

370

450

420

Speed Range

pcs /min

55-95

45-75

35 55

30-50

25 45

P.K.O Stroke

mm

30

45

45

60

60

K.O Stroke

mm

165

220

315

400

380

Main slide stroke

mm

274

346

500

620

580

Main motor

kw

55

75

110

110

132

Cut-off-die size

mm

Ф75*100L

Ф75*120L

Ф99*150L

Ф99*150L

Ф118*150L .

Punch die size

mm

Ф75*185L

Ф90*215L

Ф120*270L

Ф120*270L

Ф140*300L

Main die size

mm

Ф108*200L

Ф125*240L

Ф148*355L

Ф148*450L

Ф168*420L

Die pitch

mm

129

140

160

160

180

Machine Weight(Approx)

Kgs

52,000

72,000

130,000

160,000

200,000

Normal bolt size

mm

10-16

12-20

16-25.4

16-25.4

24-30

Shank length of blank

mm

20-150

25-200

60-300

120-400

100-350

Mechanical Dimensions(cm)

cm

600*317*272.5

830*430*320

935*460*339.5

1200*470*500

1100*490*480

REMARKS

The company keeps the right to revise above parameters. If there is any alterations, advance notice won’t be given then.

The products’ most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Features of RBF Series 5 Station Bolt Former

01

Enhanced productivity

The RBF Series 5 Station Bolt Former is designed to provide even higher productivity compared to its predecessor. Its five-station design enables the simultaneous formation of multiple bolts, allowing for faster production.

02

User-friendly interface

The RBF Series 5 Station Bolt Former features a user-friendly interface, making it easy to program and operate. It allows for quick and simple setup, minimizing downtime and streamlining production processes.

03

Robust construction

Built with sturdy materials and components, this bolt former offers excellent durability and reliability. It can withstand heavy-duty use and is designed for long-lasting performance.

04

Low maintenance requirements

The machine requires minimal maintenance, reducing maintenance costs and downtime. Routine cleaning and servicing can be easily carried out by the user, ensuring smooth operation.