Heavy Hex Bolt

The nearly 20 years that DATIAN (DT) Fasteners has specialized in the production of heavy hex bolts. Many customers need to purchase by sets. Our loyal customers usually need to source hex bolts / heavy hex head bolts together with hex nuts. As a professional heavy hex bolt factory, DT provides complete heavy hex bolt supply chain services. we are able to produce A307 B heavy hex cap screws, A193 B7 heavy hex bolts, A325 heavy hex screws, etc.

Heavy Hex Head Bolt Applications

High-strength hexagon bolts are mechanical properties of grade 8.8 or above, and they are all bolts that require heat treatment

Bolts made of high-strength steel, or bolts that require a large pre-tightening force, can be called high-strength bolts. High-strength bolts are mostly used for the connection of bridges, rails, high-voltage, and ultra-high-voltage equipment. The fracture of this kind of bolt is a mostly brittle fracture. High-strength bolts applied to ultra-high pressure equipment need to be prestressed to ensure the sealing of the container.

Application areas of high-strength bolts: Steel Fabrication, Construction of Railroad Systems, Pumps, and Water treatment, Construction of Modular Buildings, and Renewable and Alternative Energy.

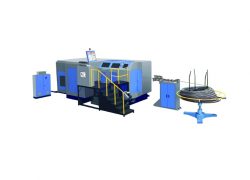

Heavy Hex Head Bolt Manufacturing Process Steps Include:

Usually, the forming of the bolt head is processed by cold heading. The cold heading forming process includes cutting and forming, single-station single-click, double-click cold heading and multi-station automatic cold heading. An automatic cold heading machine performs multi-station processes such as stamping, heading forging, extrusion and diameter reduction in several forming dies.

(1) Use a semi-closed cutting tool to cut the blank, the easiest way is to use a sleeve type cutting tool.

(2) During the transfer of short-sized blanks from the previous station to the next forming station, the metal fasteners with complex structures are processed to improve the accuracy of the parts.

(3) Each forming station should be equipped with a punch return device, and the die should be equipped with a sleeve-type ejector device.

(4) The structure of the main slider guide rail and process components can ensure the positioning accuracy of the punch and the die during the effective use period.

(5) The terminal limit switch must be installed on the baffle that controls the material selection, and attention must be paid to the control of the upsetting force.

Heat Treatment Of High-Strength Heavy Hex Screw:

High-strength nuts and bolts must be quenched and tempered according to technical requirements. The purpose of heat treatment and tempering is to improve the comprehensive mechanical properties of the heavy hex bolt to meet the specified tensile strength value and yield ratio of the product. The heat treatment process has a crucial impact on high-strength fasteners, especially their intrinsic quality. Therefore, in order to produce high-quality heavy hex head bolts, advanced heat treatment technology and equipment must be available.

As one of the leading heavy hex bolt manufacturers in China, DT Fastener possesses a complete production line of heavy hex cap screws. Feel free to contact us for more details!