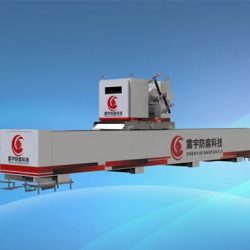

Offline Inspection Machine for Stacking Battery

Offline Inspection Machine for Stacking Battery

Seamark offline stacking battery X-ray inspection machine, which is suitable for inspection of various stacking process-type batteries. Seamark has 1 model XB5200 as such kind of machine. it is suitable for the inspection of stacking (blade) process-type cells in the lithium battery industry and adopts TDI line scanning technology and expandable inspection functions such as plate fold and tab fold. Offline inspection machine is typically used to make random inspections. It adopts a Hamamatsu X-ray tube and advanced FPD, which can help the operator to get a good effect image of the samples and help the operator to make the correct judgment. It is widely used in some labs and small battery manufacturing enterprises.

What Types Of Defects Can The Stacking Offline Inspection Machine Detect?

Angle Overhang

This refers to misalignments or protrusions in the angles of the battery components. The inspection machine can identify irregularities in the alignment, ensuring the components are properly positioned.

Large Area Folds

Large folds in the battery material can impact the battery’s structural integrity and performance. The machine is designed to identify these folds, ensuring the battery’s surface is smooth and defect-free.

Tab Creases

Tabs are critical components in batteries, connecting different layers. Creases or deformities in these tabs can lead to electrical issues. The inspection machine can detect tab creases, ensuring the tabs are in optimal condition for proper electrical connections.

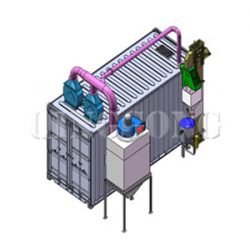

How Does Stacking Offline X-Ray Inspection Machine Work?

Stacking Offline Inspection Machine

X-ray tubes and detectors are the core components of offline X-ray battery inspection machines. The machine provides images of the internal structure with the help of the X-ray tube and detector. FPD receives and converts the X-ray signal to an industrial computer, then the software will process the received signal through an algorithm and output the X-ray image. Offline X-ray inspection machines do not need to be used with other devices, and it’s easy to place and operate.

Is the Offline Inspection Machine suitable for small-scale as well as large-scale production?

The offline inspection is suitable for random inspection. So it depends on the requirements of different battery production enterprises.

What is the typical inspection speed of SEAMARK’s Offline Inspection Machine?

Different machines have different speeds, so for accurate data, please contact the service or salesman directly.