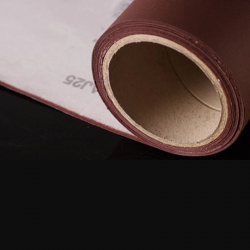

FUJISTAR: Global Leading Abrasives Manufacturer

Abrasives are materials used for grinding, cutting, and polishing other materials, typically hard and durable materials like metal, stone, and wood. General types of abrasives are made of hard and sharp particles that are bonded together into various shapes and sizes to create abrasive products, such as grinding wheels, sandpaper, and polishing compounds.

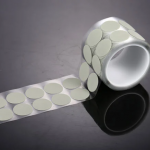

What Are Abrasives Products Used For?01Grinding and cutting: Abrasives are used to remove material from a surface, often to prepare it for further processing or to reshape it. This can include grinding down welds, cutting metal, or shaping wood. Relative products including sanding nets are for sale.02Polishing and finishing: Abrasives are also used to achieve a smooth and polished surface on materials. This can include polishing metal, removing imperfections from a surface, or smoothing out rough edges.

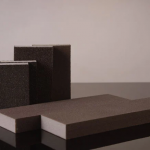

High-quality materials: Sankyo Fuji Star’s abrasives products are made from high-quality materials, ensuring that they are durable and long-lasting. This can help reduce the need for frequent replacement of abrasive products, saving time and money.

Versatile: Fujistar’s different types of abrasives can be used for a variety of applications, including grinding, cutting, and polishing. This versatility can help streamline production processes and reduce the need for multiple abrasive products.

Consistent performance: Fujistar’s custom abrasives are designed to provide consistent performance over time, ensuring that they maintain their effectiveness throughout their lifespan. This can help ensure that production processes are efficient and reliable.

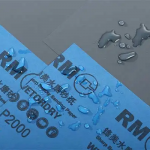

How Are Abrasives Made?AProduction of abrasive particles:Abrasive particles are typically made by crushing or milling natural materials like emery or garnet, or by synthesizing synthetic materials like aluminum oxide or silicon carbide in high-temperature furnaces.BBonding of abrasive particles:Once the abrasive particles are produced, they are typically bonded together using a variety of techniques, including resin, vitrification, or electroplating. This bonding process creates the final abrasive product, such as a grinding wheel or sandpaper.