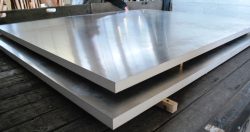

Molybdenum Sheet

Molybdenum sheet is black brown, if alkali washing is silver gray metallic luster, can be produced according to the width and thickness provided by the user, the surface is smooth, smooth, no heavy skin, layering, cracks, cracks, impurities clamping and other defects. The thickness & gt; Supply 0.7mm in hot rolled state, thickness & LT; The 0.7mm sheet is supplied in cold rolled or cleaned surface condition.

Specification of Molybdenum Sheet

Width, mm

Thickness, mm

Thickness deviation, min, mm

Flatness, %

<300mm

>0.13mm

±0.025mm

4%

≥300mm

>0.25mm

±0.06mm

5%-8%

Purity(%)

Ag

Ni

P

Cu

Pb

N

<0.0001

<0.0005

<0.001

<0.0001

<0.0001

<0.002

Si

Mg

Ca

Sn

Ba

Cd

<0.001

<0.0001

<0.001

<0.0001

<0.0003

<0.001

Na

C

Fe

O

H

Mo

<0.0024

<0.0033

<0.0016

<0.0062

<0.0006

>99.97

Application of Molybdenum Sheet

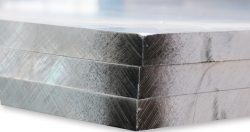

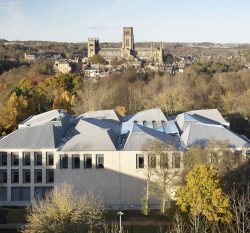

After the deformation after reaching more than 60% of the rolling process, the density of molybdenum sheet basically close to the theoretical density of molybdenum, therefore it has high strength, uniform internal organization and excellent high temperature creep resistance, which is widely used in production of sapphire crystal growth furnace reflective screen, cover plate, reflective screen in a vacuum furnace, tropical, fittings, plasma deposition sputtering target material, High temperature boat dishes and other products.

Production Process of Molybdenum Sheet

Molybdenum billet (raw material)- inspection – hot rolling – leveling and annealing – alkali washing – testing – Wenza – vacuum annealing – testing – cold rolling – leveling – shear vacuum annealing – testing – packaging.

Features of Molybdenum Sheet

01.

After chemical cleaning, it is silver gray metallic luster.

02.

Which can be produced according to the width and thickness provided by users. The surface is smooth and smooth, without defects such as heavy skin, layering, cracks, cracks, and impurities clamping.