Sheet Metal Welding

Sheet metal welding has argon arc welding, laser welding, spot welding, carbon dioxide protection welding, stainless steel sheet welding, aluminium sheet welding manual arc welding, etc. With the advent of technology, the process of sheet metal welding has evolved over the years. As one of the professional sheet metal components companies, HSJ Metal Fabrication, understands the differences between the existing welding techniques. That’s why we can make a wise decision when it comes to picking the right welding technique for any projects from our customer.

What Is Sheet Metal Welding?

Sheet metal welding involves heating and melting sheet metal parts and joining them together to increase their strength or create a single integrated product. This process is widely used in various manufacturing industries, such as automotive, aerospace, construction, and equipment production. Common applications include welding metal frames, cabinets, HVAC systems, and other metal products.

At HSJ Metal Fabrication, we have expertise in different welding techniques, enabling us to make informed decisions when choosing the most suitable welding method for each project to meet our customer’s requirements.

HSJ Sheet Metal Welding Highlights

Equipment List

5-Tig Welders, 300 amp, by Miller.

5-Tig Welder, 300 amp, by Airco.

2-Tig Welder, 250 amp, by Ltech.

2 Miller heliarc welder.

2-Tig Welder, 250 amp, Cobramatic for aluminum.

2-Tig Welder, 250 amp, Miller Syncrowave

2-Tig Welders, 330 amp, by Miller.

2-Mig Welder, Miller, 300 Amp.

2-Airco wire feed.

2-Miller CP300, wire feed.

2-Welder Airco.

2-Acme spot welder, 30″ arm, water cooled, air timer.

2-TRW stud welding machine.

5-Gas powered field welder, Miller

5-Portable welder

Industry Area

Medical

Oil & Gas

Defense

Transportation

Packaging

Heating & Cooling

Building Materials & Construction

Engineering

Electrical Equipment & Electronics

Aerospace

Commercial Display

Industrial Equipment

Custom Sheet Metal Welding Tolerances

Size(mm)

Grade1

Grade2

Grade3

Grade4

Grade5

Gerneral Angle

0-30

±0.1

±0.2

±0.3

±0.4

±1

90degree, ±1

31-120

±0.15

±0.25

±0.4

±0.7

±2

121-250

±0.2

±0.3

±0.6

±1

±2

/

251-500

±0.3

±0.5

±1

±1.8

±2

Above 500

±0.5

±0.8

±1.5

±3

±3

HSJ Materials for Sheet Metal Welding

Aluminum (2A21/3003/5052/5083/6061/6082 /8011)

Carbon Steels(Q235,SPHC ,SPCC,SPCD ,SPCE ,ST,ST12,ST13,ST14,ST15,ST14-T )

Stainless Steel ( 304,304L ,312 ,316,317,321,347,904L,440,17-4ph,430 etc.)

Copper (C1020、C1100、C2100,2200,2300,2400)

Brass ( H62、H65、H68、H70、H80、H90、C2600、C2680、C2700、C5210、C5191、 C51000、QBe2.0、C1100、T2)

Other Non-Ferrous Alloys

Material

Features

Thickness(mm)

Electro-galvanised steel (SECC)

Fingerprint-resistant, with excellent corrosion resistance and good paintability, while maintaining the processability of cold rolled sheet

0.8, 1.0, 1.2, 1.5, 2.0

Cold rolled sheet (SPCC)

No rust resistance, surface plating or baking paint is required.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Galvanised Steel Sheet (SGLD)

A multi-phase alloy containing aluminium and zinc rich material with beautiful appearance, scratch resistance, corrosion resistance and much higher capacity than SGCC.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

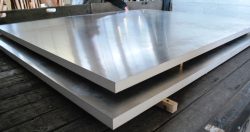

Aluminium sheet (AL)

Lower strength, excellent forming properties, good weldability and corrosion resistance, and good heat dissipation capability.

0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0

Hot-dip galvanized steel plate (SGCC

Beautiful appearance, there are two kinds of zinc flowers, small zinc flowers, it is difficult to see the zinc flowers; large zinc flowers can obviously see the kind of hexagonal flower blocks. It has corrosion resistance, paintability, formability, and spot welding.

0.8, 1.0, 1.2, 1.5, 2.0, 3.0

Benefits of Sheet Metal Welding

Save metal materials and reduce structural weight. Simplify processing and installation procedures and improve production efficiency.

The structural strength is high, and the joint sealing is good; it provides greater flexibility for structural design. The welding process is easy to realize mechanization and automation.

Custom Sheet Metal Fabrication Welding

HSJ Metal Fabrication Co., Ltd is a specialized sheet metal fabrication company located in Shenzhen, China. We offer industrial and commercial fabrication services, including OEM, ODM, and customized solutions for size, color, surface treatment, logo, assembly, or packing. Since 2015, we have been committed to providing dependable and excellent customer service for every project we undertake.

Choose HSJ for Sheet Metal Welding

Experienced and Reliable Sheet Metal Fabrication Company

Qualified Sheet Metal & Welding has been serving small and large clients for over 8 years. We have successfully completed thousands of projects for commercial, industrial, pharmaceutical, and aerospace clients from China and abroad. Our commitment to innovation and hard work has earned us a reputation as a reliable and experienced sheet metal fabrication company.

Customized Solutions for Your Sheet Metal Needs

At HSJ Metal Fabrication, we use the highest-quality materials, the best cutting-edge technologies, and the most efficient welding processes to ensure the accuracy and precision of our work. Our 20 years experienced engineer and professional service teams have successfully completed high-level customer requirements. We offer customized solutions for each client and ensure the most accurate and precise workmanship available in this field.

Associated with the Associated Builders & Contractors Association

We are affiliated with the Associated Builders & Contractors Association and are committed to providing the broadest range of sheet metal and welding services to the commercial, industrial, and pharmaceutical industries.

Contact us now for all your sheet metal needs!

Available Sheet Metal Welding Process

HSJ sheet metal welding comes with various types of sheet metal welding, including gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance welding.

Typical types of sheet metal welding processes including, MIG welding, TIG welding, resistance welding, projection welding, robotic MIG and TIG welding, and laser welding on various metallic and aluminum alloy surfaces as well as on stainless steel and iron.

MIG welding

MIG welding, also called MAG welding, is a continuous wire welding process where a shielding gas ensures firing bath protection. MIG or MAG welding is used where high productivity and high flexibility of use are required. While MIG welding requires the use of inert gas, MAG welding is carried out through an active gas. MIG welding can be also performed on thin metal, such as thin steel or aluminum.

TIG welding

TIG welding is one of the most popular welding methods since it provides high-quality components. Especially indicated to weld thin parts, it can be used for both continuous and spot welding.

Resistance welding

Resistance welding is a metal fusion welding technique where the material is heated by electrical resistance. Generally used to weld iron and steel, resistance welding guarantees high-quality standards on welded components while ensuring time and cost savings. If you want to learn more about resistance welding, we will explain everything to you.

Projection welding

Projection welding requires studs to be placed on the metals to be welded. During the metal welding process, the welding current is focused on the stud that heats to obtain complex welds, with final results that ensure excellent quality at low costs. Basically, projection welding is a type of resistance welding that uses projection.

Robotic TIG MIG MAG welding

Robotic welding is performed by programmable industrial robots. Mainly used in situations that require repeated welding, it guarantees repeated precision which is hard to achieve with manual welding. Greater precision and higher productivity are the main advantages of robotic welding.

Laser welding

Laser welding allows metals and metallic alloys to be welded, creating a thin and deep weld, with reduced heat deformations thanks to the reduced heat, even on materials that could not otherwise be welded. Precision, cleanness, minimal heat input, and fast manufacturing are just a few of the advantages of laser welding.

Welding metals: the metals that we process in Minifaber

The mentioned welding processes apply to a wide range of metals and sheet metal components that can be welded to create semi-finished and finished products. Through these processes, HSJ can provide welding of iron, aluminum, stainless steel, and copper.

Iron welding

Iron welding is widely employed in several industrial sectors. Thanks to a cutting-edge machinery and the extensive know-how raised through the years, Minifaber can provide iron welding services with the highest cleanness and precision. There are 5 different ways to carry out iron welding: HSJ can help you choose the right one!

Aluminum welding

Renowned for its ductility, lightness, and oxidation resistance, aluminum is employed in every sector in which these qualities are required, such as the aerospace sector and the transport sector. HSJ is focused on various types of aluminum welding: aluminum MIG welding, aluminum tig welding, and other welding processes to manufacture aluminum according to the desired output.

Stainless steel welding

Stainless steel is a special steel alloy that boasts important qualities such as rust resistance, corrosion resistance and high hygiene standards. For this reason, stainless steel is widely employed in the food industry. HSJ provides stainless steel welding services for any specific requirements and offers three different services of stainless steel welding.

Copper welding

Copper is employed in the electrical and electromechanical sectors for its high conductivity and ductility. Copper welding is among the services provided by Minifaber for national and international customers.

Metal Fabrication Welding Application

Computer enclosure

Electronic part

Sheet Metal Welding Related FAQs

How to weld thin metal?

TIG and MIG are both ideal when it comes to welding thinner metal sheets. However, for an extremely thin sheet of stainless steel and aluminum, the TIG method is preferred as it allows for better control over heat input.

What is the thinnest sheet metal that can be welded?

Which Weld Is stronger, MIG, TIG or Arc?