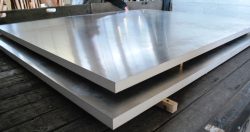

SHEET METAL FABRICATION SERVICES

Whether you need single functional sheet metal prototypes or complete assembled sheet metal products, LC Rapid customs sheet metal fabrication services offer an affordable and super quality sheet metal fabrication plant solution for your manufacturing needs. We have the full capability to handle every stage of your sheet metal fabrication projects, including bending, lasering cutting, punching, welding, stamping, assembly and other precision sheet metal manufacturing processes. Sheet metal is one of the commonly-used methods of manufacturing metal parts. Designers and engineers use it to create a wide variety of products with different shapes and sizes, and regard it as an ideal option for producing low to high volumes of the metal parts. Sheet metal is widely used in manufacturing different parts of custom auto sheet metal fabrication, from the smallest automotive interior component to entire enclosures for electronic devices.

Custom Metal Fabrication Services

Custom metal fabrication services is the process of forming a metal sheet mechanically. The sheet metal fabrication service processes of forming parts include: lasering cutting, turret punching, folding, forming, bending, rolling, welding, assembly process. The sheet metal parts can be sandblasted, brushed, anodized, powder coated, painted, and etc. Sheet metal parts are widely used in the fields of electronics, mechanical, telecommunications, automotive industry, consumer goods and so on. In detail, as one of the top sheet metal fabrication companies, our custom sheet metal fabrication can be applied in aerospace sheet metal fabrication, auto sheet metal fabrication, steel sheet fabrication and sheet metal fabrication tolerances.

Advantages of Sheet Metal Fabrication Service

Low CostLow Cost

Sheet metal fabrication generally has a significantly lower material and set-up cost when compared to machining.

DurabilityDurability

Sheet parts are highly durable that make them suitable for functional prototypes and end-use production.

Large-scale Production PerformanceLarge-scale Production Performance

Sheet metal machining is an ideal process from a single component up to custom production runs 10.000+ pieces.

Rapid TurnaroundRapid Turnaround

Using the advanced Sheet Metal fabrication machines, we can produce light weight, high strength parts in just a few days.

Custom FinishesCustom Finishes

Select from a wide array of finishes, including brushing, polishing, anodizing, plating, powder coating, and painting.

Electrical ConductivityElectrical Conductivity

Sheet metal parts are known for the conductivity, which make them great for electromagnetic shielding.

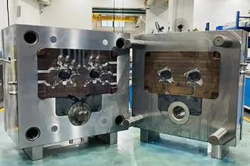

Sheet Metal Fabrication Process

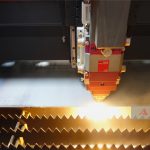

Cutting

Bending

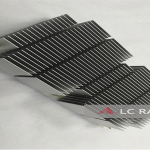

Stamping

Welding

Precision Sheet Metal Manufacturing Tolerance

Unless otherwise specified, we comply with below tolerance table for sheet metal parts.

Feature

Tolerance

Cutting feature

± .00787’’ (0.2 mm)

Bend angle

± 1.0°

Bend to edge

+/- 0.010” (0.254mm)

Precision Sheet Metal Manufacturing Material

Aluminum

Stainless steel

Mild steel

Copper

6061-T651

304

1018

C101

5052-H32

316/316L

Galvanized Steel

C110

301

260 (Brass)