PCB for Industrial Control

Common Uses of PCBs in Industrial Control

Instrumentation

In the instrumentation industry, PCBs can be used as carriers for circuit boards and sensors to provide precise circuitry and control functions for sophisticated test and measurement equipment.

Motor control

In motor control, PCBs can be used to implement control algorithms, real-time feedback and drive circuits to help achieve efficient, reliable and energy-efficient motor control.

Photovoltaic inverters

In photovoltaic inverters, PCBs can be used to achieve efficient energy conversion and maximum power point tracking, helping to achieve optimal performance of solar power systems.

Energy storage systems

In energy storage systems, PCBs can be used to achieve battery management, charge control and energy conversion to help realize efficient and reliable energy storage systems.

New energy charging stations

In new energy charging stations, PCBs can be used to realize functions such as charging control, data transmission and safety protection, helping to realize fast, safe and intelligent charging services.

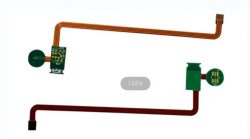

Mobile charging gun

In mobile charging guns, PCB can be used to realize charging circuits, communication interfaces and safety protection, helping to realize portable, fast and safe charging service.

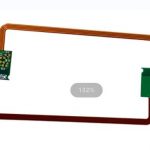

RFID identification

In RFID identification, PCBs can be used to implement antenna and reader circuitry, signal processing and data transmission to help achieve efficient and accurate RFID identification services.

Advantages of Our PCBs for Industrial Control

Stability

Electronic devices are often required to operate in harsh operating environments. Our products are precision designed and high quality manufactured with excellent stability and reliability, which can adapt to these harsh working environments and ensure long-term stable operation of the equipment.

Versatility

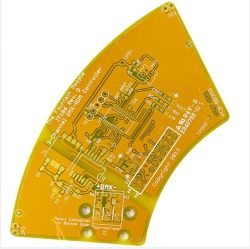

The wide variety of electronic devices requires PCB products of different shapes, sizes and functions to suit different application scenarios. Our products can be customized to meet the needs of a variety of different applications.

High performance

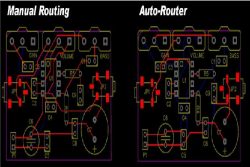

Electronic devices need high-performance PCB products to ensure the accuracy, stability and responsiveness of the equipment. Our products use high-quality materials and advanced production processes to enable high-density, high speed and high-accuracy data transfer.

Cost-effectiveness

The cost and performance of the equipment are two major factors for companies to consider. Our products can be customized according to customer needs with short production cycle while having high quality and cost-effectiveness, which can help companies reduce production costs and improve market competitiveness.

WordPress plug-ins are not directly related to PCB (Printed Circuit Board) design for industrial control. WordPress is a content management system primarily used for website development, while PCB design involves creating circuit boards for industrial control applications. However, WordPress does offer various plug-ins for website optimization and functionality.