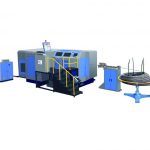

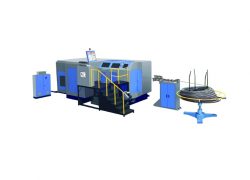

QLBF Series 3 Station Bolt Former

QLBF Series 3 Station Bolt Former

The QLBF Series 3 Station Bolt Former is a cutting-edge equipment designed for the efficient and precise production of bolts. Equipped with three stations, it enables essential operations like heading, thread rolling, and trimming in a single machine. As one of the professional cold forming machine manufacturers, Rainbow offers fully automatic nut bolt making machine that has high productivity, exceptional precision, and flexibility for manufacturers in need of medium to large scale bolt production. The QLBF Series 3 Station Bolt Former is an ideal choice for achieving optimal efficiency and superior quality in bolt manufacturing processes.

Specifications of QLBF Series 3 Station Bolt Former

Main Technical Data of RBF Series 3-station High Speed and Fully Automatic Cold Heading and Forming Machine

Model

Unit

RBF-63S

RBF 83S

RBF 83L

RBF-103S

RBF-103L

RBF-133S

RBF-133L

Forging station

No.

3

3

3

3

3

3

3

Forging force

Kgs

38,000

65,000

65,000

85,000

85,000

120,000

120,000

Max cut-off dia.

mm

Ф8

Ф10

Ф10

Ф12

Ф12

Ф15

Ф15

Max cut-off length

mm

80

75

135

100

190

140

250

Speed Range

pcs/min

160-260

140-240

110-180

120-200

85-140

100-160

60-100

P.K.O Stroke

mm

12

12

16

15

15

26

25

K.O Stroke

mm

65

50

115

80

160

100

230

Main slide stroke

mm

110

106

193

150

280

200

350

Main motor

kw

11

18.5

18.5

18.5.

22

30

30

Cut-off-die size

mm

Ф30*45L

Ф53*56L

Ф30*50L

Ф45*59L

Ф45*59L

Ф63*69L

Ф55*70L

Punch die size

mm

Ф40*90L

Ф45*95L

Ф45*140L

Ф53*115L

Ф53*112L

Ф60*130L

Ф60*179L

Main die size

mm

Ф50*85L

Ф60*80L

Ф60*150L

Ф75*108L

Ф75*200L

Ф86*135L

Ф86*265L

Die pitch

mm

60

70

70

90

90

98

110

Machine Weight(Approx)

Kgs

8,000

11,000

14,000

14,000

20,000

23,000

32,000

Normal bolt size

mm

3-6

5-8

5-8

6-10

6-10

8-12.7

8-12.7

Shank length of blank

mm

10-65

15-55

25-105

15-70

30-150

20-100

70-210

Mechanical Dimensions(cm)

cm

380*212*147

420*220*173

455*235*208

410*250*180

570*240*230

455*260*196

780*260*270

REMARKS

The company keeps the right to revise above parameters. If there is any alterations , advance notice won’t be given then.

The products’ most applicable production speed is decided by the product shape, size and material.

Maximum material shearing diameter and product size listed in the table can be calculated according to medium carbon alloy steel. It is equal to 10.9 grade high Intensity screw.

Features of QLBF Series 3 Station Bolt Former

01

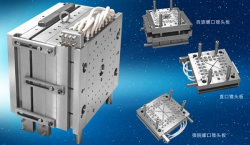

Compatible Reversible Nuts and Fixed Bolt Clips

Reversible nuts and fixed bolt clips that match with RBF serial multi-station parts forming machine.

02

Swing Transfer Conveyance

Transfer conveyance of rotary swing mode and transfer force of adjustable pneumatic mode ensures stable and reliable work-piece conveyance and high speed operation of the machine. The first station clip can automatically loose short dimension feeding, stop and alarm.

03

Coordinated Reciprocating Movement

Reciprocating movement of clipping table and opening/closing actions of the clips are both driven by a jpint intermediate shaft to ensure the coordinated actions.

04

Optional CNC Type Adjusting Mechanism

Is rear knock-out mechanism. Rear knock-out mechanism of various stations can be respectively and independently adjusted. Last station can. Before being kicked out, dead – point position of all models keeps the same. Some models can choose to add hand – wheel type or CNC type rear knock-out threaded pipe adjusting mechanism.

05

Independent Adjustment and Overload Protection

Is punch knock – out mechanism of RBF serial model. Punch knock – out coincides with back action of machine slider. After the work piece is shaped, it stays in the mould and then being kicked out by rear knock – out mechanism. It avoids being talken away by the punch and then get deformed, Various stations of front knock – out positions can be independently adjusted. All the front lead – out mechanism have knock – out force over- load protection devices.

06

Automatic Pawl Lifting and Noise Reduction

Is electric feeding mechanism, In return stroke, pawl can be automatically raised by air cylinder and be separated from ratchet wheel. It not only removes friction and noise, but also prevents ratchet wheel from reversal operation.