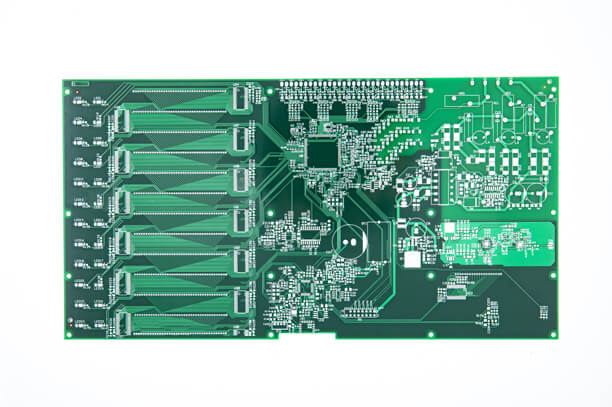

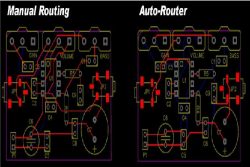

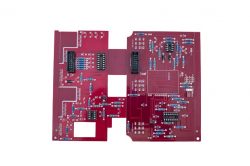

PCB Layout/DFM

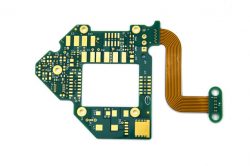

Saving time and cost of research and development, helps product launch quickly. Considering also the possibility of mass production.

Helping our customers bring new products to market in a fast, efficient and highly strategic manner is what makes us stand out as an electronic contract manufacturer like Fastlink Electronics.

In the early stages of new design work, Fastlink Electronics strives to mitigate future production barriers and aims to optimize the production capacity of the product while keeping overhead costs low. Based on our actual manufacturing experience in past projects.

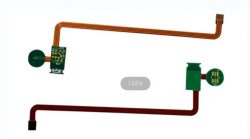

Design PCB products especially suitable for PCB assembly equipment and batch manufacturing process for customers.

What Electronics Products Fastlink Electronics has ever Designed For?

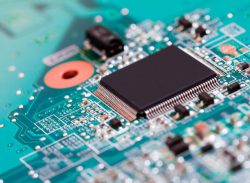

Because so many industries use PCBs, they are almost everywhere, from small consumer equipment to large mechanical equipment. Fastlink Electronics has helped our customers from different industries with design work:

Medical Devices such as Medical imaging systems, Monitors, Infusion pumps, and Internal devices

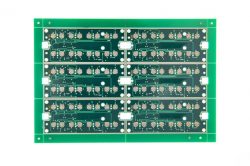

LEDs such as Residential lighting, Storefront lighting, Automotive displays, Computer displays, Medical lighting

Consumer Electronics: Communications devices, Computers, Entertainment systems, Home appliances

Industrial Equipment: Manufacturing equipment, Power equipment, Measuring equipment

Automotive Components: Entertainment and navigation systems, Control systems, Sensors

Aerospace Components: Power supplies, Monitoring equipment, Communication equipment

Maritime Applications: Navigation systems, Communications systems, Control systems

Safety and Security Equipment: Security cameras, Smoke detectors, Electronic door locks, Motion sensors, and burglar alarms

Telecommunications Equipment: Telecom towers, Office communications equipment, LED displays, and indicators

Military and Defense Applications: Communications equipment, Control systems, Instrumentation

If DFM is Not Implemented Properly, These Unwanted Problems Can Potentially Arise During Volume Circuit Board Assembly and Manufacturing Operations:

Excessive production costs

Undesirable quality issues

Problems with functional test

Increased risk of inadequate quantity yields