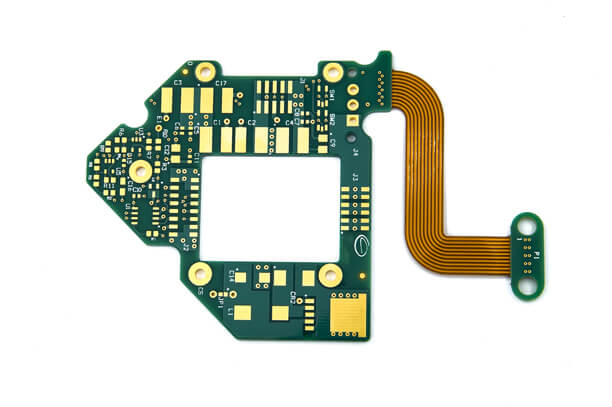

Rigid-Flex PCB

Fastlink helps customers finish a lot of projects including smart phone, smart TV, tablet pc, laptop, smart wearable devices, TWS etc. We can produce a maximum 24L rigid pcb plus 8 layer flex pcb.

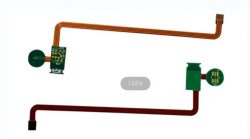

Rigid-Flex PCB can safely bend into small and complicated electronics, making them suitable for modern devices like smartphones. Because of their good performance in absorbing shock and vibration in high stress environment, they are more and more widely used.

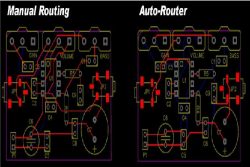

Fastlink Electronics’ professional engineers combine standard circuit board construction with flexible design, which is suitable for situations requiring more durability. We have successfully provided our customers with tens of thousands of excellent manufacturing cases of Rigid-Flex PCB.

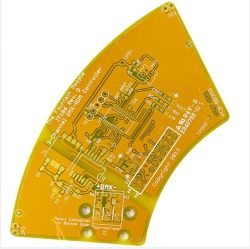

What Are The Applications Of Rigid-Flex PCBS

Rigid-Flex PCB not only maximizes space and weight but also greatly improves reliability, eliminating many of the needs for solder joints and fragile and fragile wiring prone to connection problems. So the Rigid-Flex PCB is more and more widely used in various fields, from smart devices to mobile phones and digital cameras. Because of its excellent weight reduction ability, the Rigid-Flex PCB is also increasingly used in medical devices such as pacemakers. There are also intelligent control systems and electrical applications, including test equipment, tools, cars, etc,