Production Process and Performance of Color Steel Sandwich Panel Machinery Equipment

The sandwich panels made of color steel sandwich panel machinery equipment are made up of two layers of color coated steel sheets, bonded with foam or rock wool. The color steel sandwich panel is widely used in the construction of large industrial plants, warehouses, gymnasiums, cold storage and sandwich and other fields because of its excellent performance.

Its production process and performance are as follows:

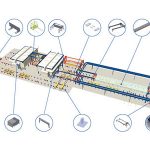

The color steel sandwich panels, produced by the sandwich panel machine line, are made of three layers of material. The outer layer is made of high density color coated steel sheets or aluminum foil on the bottom. The core material is a foam board, rock wool, or glass wool cotton. The coated steel plates and foam (or rock wool) boards are bonded together with thermosetting glue. The outer metal plate can be ordinary steel plate, aluminum plate or galvanized iron plate. The foam (or rock wool) plate is cut into the required thickness, and the adhesive is bonded to the metal plate. Generally, the black or white special glue is used as the adhesive.

The color steel sandwich panel has the triple functions of heat preservation, waterproof and heat insulation, and it is mainly used for the wall and roof of buildings. Therefore, the quality of the three-layer material of the color steel sandwich panel will directly affect the service life, durability and building safety of the color steel sandwich panel.

The color steel sandwich panel is a five layer composite material, that is, one steel sheet-rubber-foam(or rock wool) plate-glue-one steel plate. The thickness ratio of each layer is 0.5:0.3:100 (commonly used thickness):0.3:0.5.

A major feature of color steel sandwich panels is that the connection between panels and panels is filled with foam (or rock wool) plate or soft foam strip, and no cold and hot bridge will appear. The thermal resistance value of color steel sandwich panel is very large, and the thermal conductivity is very small, which is 1/20 of brick.

From the sound insulation principle, the sound insulation performance of the light density structure is poor. When the sound insulation capacity needs to be improved, other auxiliary measures should be taken, such as filling loose sound-absorbing material in the middle of the double-layer wall, strengthening the assembly gap sealing, etc. From the perspective of fire performance, the color steel sandwich panel produced by the sandwich panel production machinery is composed of two layers of non combustible materials (steel plate) sandwiched with refractory materials, and the oxygen index value of flame retardant rock wool board reaches more than 30.

The thickness of the outer color coated panel is usually 0.5mm, 0.6mm, 0.75mm, etc., and the thickness of upper and lower surface steel panels is the same. The core board is polystyrene foam, and its thickness is usually 50mm, 75mm, 100mm, 125mm, 150mm, 200mm, etc. The adhesive is used between the color coated steel panel and the core plate, and the thickness of the adhesive is about 0.3mm.