SCADA Remote Terminal Unit RTU

As one of the top SCADA RTU manufacturers,Remote terminal unit scada is a general term for various remote monitoring installed in the distribution network, SCADA remote terminal units has functions such as data collection, control, and communication.

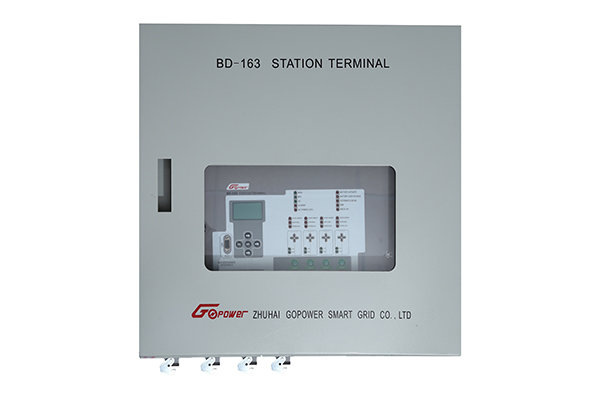

BD-163 distribution automation master terminal unit in SCADA RTU is a new generation of China power distribution box based on the latest generation of automated remote terminal technology from China SCADA RTU manufacturers. The remote terminal unit RTU like our MCC cabinets electrical is the eyes and limbs of the power distribution automation system. The operating status of RTU in SCADA system is related to the data reliability, performance accuracy and operational safety of the power distribution automation. When the configuration is correct and the operation is normal, the SCADA RTU system realizes the correct operation of switches, rapid fault isolation and power restoration, thereby improving power supply reliability.

Features of Remote Terminal Unit SCADA

Remote terminal unit rtu With “communication”, the SCADA RTU system has a “remote maintenance” function.

Flexible configuration, all protection functions have a separate retreat.

The RTU for SCADA system has a complete self-checking function to detect the working conditions of each part online.

The closing and closing circuit adopts an anti-misoperation design and has an anti-missing function.

Applicable to analog acquisition, state quantity acquisition, local and remote control switch closing of 4-12 switch.

24 channels can be controlled by expansion.

By selecting different configurations, remote terminal unit can meet the needs of “Three Remote” and “Two Remote” of the State Grid and South Grid.

Meet the special requirements of all parts of the country (such as Shandong, Beijing, Guangdong, etc.)

Zero-sequence current setting adaptive function, no manual setting required.

Meet the specific requirements of “one or two integration”.

The core RTU unit can be flexibly configured to shade vertical, shaded horizontal, outdoor vertical, an d group screen.

Function of RTU in SCADA System

Distribution Terminal Unit-DTU installation location: indoor and outdoor opening and closing station, power distribution room, knife lock chamber, box change, switch, it can detect line fault and overload status function, and can detect line zero sequence overvoltage, zero sequence overcurrent, line overload, line overcurrent, phase-to-phase short circuit protection, etc. At Zhgopower scada rtu manufacturers, It can be flexibly set to alarm and trip action. And record the fault event.

The main functions of the scada remote terminal unit system are

RTU unit realize comprehensive coverage and monitoring of the operating conditions of power distribution terminals, and quickly retrieve and locate each terminal through the terminal list column;

RTU in SCADA RTU system realize remote monitoring of distribution terminal channel working conditions and board status, and timely alert terminal equipment defect information through the event warning window;

Remote terminal unit in SCADA realize the remote query of the fixed value setting of the SCADA in electrical power system, the content of the information table and the program version, and complete the program upgrade, the fixed value placement, and the modification of the information table remotely through the remote setting bar;

RTU for SCADA realize the remote query and download of the information in the memory of the power distribution terminal, such as remote signal displacement, over-current alarm, remote control operation record and other local information.

What is RTU in SCADA

Different from the and feeder remote terminal unit, the remote operation and maintenance system of the remote terminal unit in SCADA, Remote terminal unit RTU is composed of a communication management server, a Web server, network security protection equipment, and a maintenance workstation: the communication management server is used to provide direct communication with remote terminals and collect status information and parameter information of each SCADA remote terminal unit. At Zhgopower scada rtu manufacturers, The data gathered by remote terminal unit in SCADA is forwarded to the web server according to the data requested by the web server, and the remote terminal unit SCADA parameter setting command issued by the webserver is forwarded to the terminal; the web data server is used to provide a high-performance network service to provide users with browsing and modifying remote terminal unit RTU parameters and status. The interface also displays terminal real-time letter and wish data, and realizes various functions of human-computer interaction.

Remote Terminal Unit vs PLC

RTU is the basic unit of SCADA system, which is an electronic device installed on a remote site to monitor, measure and collect sensors and equipment installed on a remote site. PLC is a programmable logic controller, which performs data collection and instruction processing in the field station. Compared with the PLC, there are three main advantages:

Feeder remote terminal unit RTU is generally not restricted by the geographical environment and can be installed near the outdoor on-site measurement point.

Since SCADA RTU is not restricted by the working environment, its technical specifications are required to meet harsh environment requirements and specific requirements. Its data storage capacity is large, the analog quantity acquisition ability is strong (up to 24 channels), and the analog function is far more powerful than PLC.

The RTU SCADA communication function is powerful. It will finally transmit the collected analog, switch, and digital information to the dispatch center, and the dispatch center is sometimes thousands of miles away, it is required to have a remote communication function. Although PLC also has a communication function, it is limited to the short-distance transmission of data within the plant station, and its communication function is slightly inferior to that of RTU.