DF Floating Seal

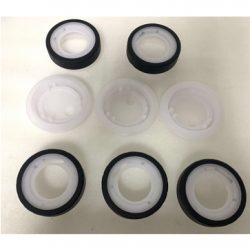

Heavy Duty seal consists of two separate metal seal rings and two square o-rings that provide elastic compression within housing bores and it also called square bore face seal, HDDF.

Fuyote available heavy duty seal sizes: 59~800mm

Metal Seal Ring Material: Fuyote’s metal seal rings are manufactured of high alloy cast iron. Fuyote offers two kinds of material for seal rings.

Elastomer components material defines its temperatures and pressure. Fuyote offers three kinds of materials for o-rings: NBR, HNBR, and Silicone.

Advantages of heavy duty seals: easy to process housing bores and highly sealing reliability.

Primary Applications: off-road and tracked vehicles, conveyors and construction equipment, agricultural machinery and mining equipment.

Two metal sealing rings interact to create a sealing surface that is perpendicular to the axis. O-rings transfer pressure from the housing to these sealing rings, enabling one of the metal sealing rings to rotate with the housing while the other remains stationary. This results in relative motion between the two mechanical face seals.

The movement between these two face seals generates an oil film on the contact surface. This oil film is essential for effective sealing. As the parts rotate, the contacting surfaces form a contact band that typically ranges from 0.008 inches (0.2mm) to 0.02 inches (0.5mm) in width. This contact band retains the oil lubricant and resists the intrusion of foreign materials. Over time, as wear occurs, the contact band may shift inward. However, the elasticity of the O-ring compensates for this movement, ensuring that the mechanical face seals maintain their precise position and stability.

Key advantages of these seals include their resistance to wear and corrosion, resulting in a long service life and maintenance-free operation. They also exhibit exceptional sealing capabilities, effectively protecting against external contaminants like abrasive substances, moisture, chemicals, oil, and grease. Furthermore, these seals are self-centering, which helps compensate for shaft eccentricity or misalignment. Additionally, the presence of oil between the seal faces enables them to lubricate and cool, allowing for higher rotational speeds.