CNC METAL MACHINING

In CNC metal machining process, the main CNC metal machining materials are iron, CNC aluminium, copper, titanium, alloy steel, aluminium alloy, etc. The processing technology in the CNC metal machining factory mainly includes turning, milling, grinding, boring, and composite processing. Richconn, as a well-known CNC metal machining manufacturer in china, is professional in producing machining metal parts, contact us and we will provide you with high-quality metal CNC services.

Why Choose CNC Metal Machining?

Flexible and efficient production

CNC metal machining makes custom CNC metal parts easier and has been considered the best way to ensure high standards in metal machining and part manufacturing. All processes can be set up using adjustable fixtures and automated machine positioning systems, making CNC machining metal possible to respond to production schedules with greater flexibility and productivity.

High accuracy and repeatability

CNC metal machining allows a higher level of precision and accuracy. Production is completely automated by the program and the machining process is continuous, every part or prototype will be replicated to the first one, making the machining process fast and easy and giving a completely consistent output.

Eliminate labor and reduce costs

Due to technological developments, machining in the manufacturing industry has been automated. The process of CNC metal machining is mainly controlled by computers or robots, avoiding the process of long processes in production lines, reducing hardware investment and workload, saving a lot of time and effort, and thus reducing production costs.

Why Choose Richconn as Your CNC Metal Machining Supplier?

As a CNC metal machining manufacturer, Richconn provide high-quality CNC metal parts and metal lathe services.

Fast,Reliable Delivery

We understand time sensitive requirements of metal CNC services and react quickly.

Rich Experience

We have decades of experience in metal lathe services for all industries and we work with your project engineers to ensure understand of sheet CNC requirements.

Design for machining metal parts

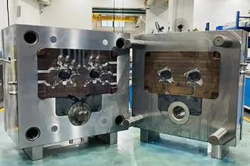

When you upload your 3D CAD file to request a quote, we’ll analyse your part geometry to identify any features that may be difficult to CNC metal sheet machine such as tall, thin walls or holes that cannot be threaded.

How does CNC Metal Machining Work?

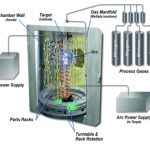

CNC metal machining is a high-efficiency automated machine tool for machining complex-shaped workpieces consisting of mechanical equipment and CNC systems. CNC machining sheet metal tools are equipped with tool storage with an automatic tool change function, and the workpiece can be multi-process machining after a single set-up.

The CNC control system can control the CNC machining metal tool according to different processes automatically change tools, tooling, select the spindle speed, feed, etc., can be completed continuously by drilling, boring, milling, reaming, tapping and other processes, thus greatly reducing the workpiece clamping, measuring and machine tool adjustment and other auxiliary setup time, suitable for machining more complex shapes, high precision and repeatability requirements of the CNC metal parts.