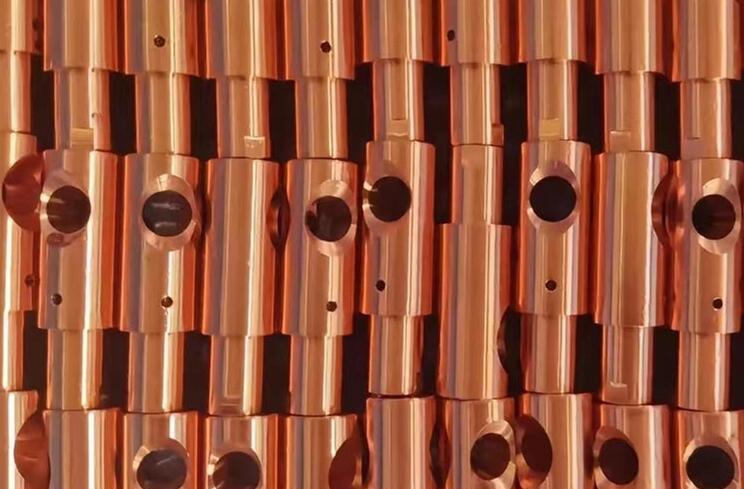

Copper Machining

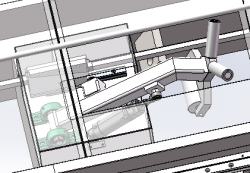

Elevate your projects with Falcon MFG’s precision copper machining services. Our specialized CNC capabilities expertly handle various copper grades, ensuring accuracy and quality. From intricate electronic components to durable fittings, our skilled team crafts precision-machined copper parts with finesse. Whether it’s C101 (Oxygen-Free) or C110 (ETP), our state-of-the-art facilities and commitment to excellence make Falcon MFG the trusted choice for diverse industries. Experience the unmatched quality and reliability that define our copper machining services, setting new standards for precision and craftsmanship in your applications.

Advantages of Copper in CNC Machining

Copper’s versatility makes it a standout choice in CNC machining. With excellent thermal and electrical conductivity, it suits applications in electronics and heat exchangers. Its malleability allows for intricate designs, while its corrosion resistance ensures durability. Falcon MFG harnesses these advantages, offering CNC-machined copper components that excel in various industries. From electrical connectors to intricate parts, copper’s unique properties make it an ideal material, and our expertise transforms it into precision-engineered solutions for superior performance and reliability.

Common Copper Grades, Surface Finishes, Machined Copper Products

Falcon MFG delivers precision copper machining services, specializing in common grades like C101 and C110. Our skilled team crafts high-quality components with superior finishes for diverse applications.

Common Copper Grades:

C101 (Oxygen-Free Copper): Known for high electrical conductivity.

C110 (Electrolytic Tough Pitch Copper): A versatile grade with good electrical and thermal conductivity.

C145 (Tellurium Copper): Enhanced machinability with the addition of tellurium.

Surface Finishes for Machined Copper Parts:

Polished Finish: Smooth and reflective for aesthetic appeal.

Tarnish Resistant Coating: Protection against corrosion.

Chemical Patina: Adds an aged or antique appearance.

Electroplating (Gold, Nickel): Enhances durability and aesthetics.

Machined Copper Products:

Electrical Connectors: Precise components for electrical applications.

Heat Exchanger Parts: Utilizing copper’s excellent thermal conductivity.

Decorative Components: Crafted for aesthetics and functionality.

Precision Fittings: Machined for durability and reliability.