Shot Blasting Room

Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. The shot blasting chamber is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The best sandblasting equipment clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. So you can call it air blasting machine or air powered sandblaster. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on.

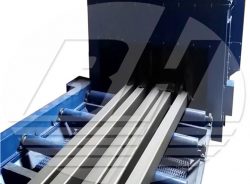

Sand Blasting Cabinet

Some people also call sand blasting machines, sand blasting tank, portable sandblaster, open sandblasting machines and so on. The names are different, but they actually have the same meaning. Can working separated, but in most case it work with shot blasting room.

Sand Blasting Room

Sand blasting room is special equipment designed to meet specific process requirements. Through shot blast cleaning, the dirt, oxide scale, welding slag and waste paint on the surface of the complex workpiece can be removed. After shot peening, the surface of the workpiece can be smooth, the internal stress of the workpiece can be reduced, the surface of the workpiece can be strengthened, and the purpose of improving the surface and internal quality of the workpiece can be achieved. For the sandblasting equipment price, please get a quote.

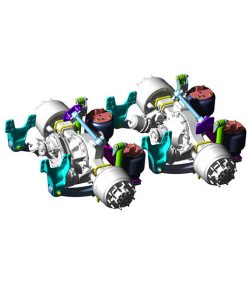

Sand Blasting Container

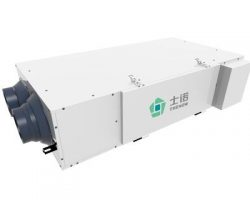

Industrial sandblasting equipment for sale is mainly composed of shot blaster assembly, shot blasting room, trolley transportation system, dust removal system, electrical control system and other parts.

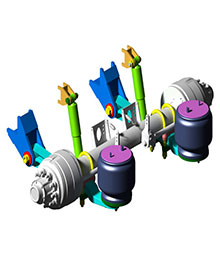

Shot Blasting Booth

The grit blasting booth is special equipment designed to meet specific process requirements. Through sandblast cleaning, the dirt, oxide scale, welding slag and waste paint on the surface of the complex workpiece can be removed, the surface of the workpiece can be smooth, the internal stress of workpiece can be reduced, the surface of the workpiece can be strengthened, and the purpose of improving the surface and internal quality of workpiece can be achieved.

https://www.qdbhmachinery.com/products/shot-blasting-room/