LOADER AND UNLOADER

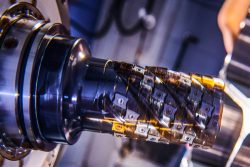

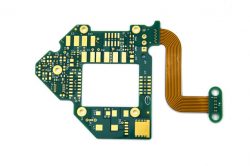

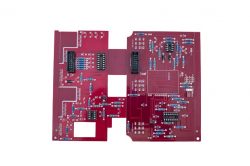

The PCB loader and unloader machine have a stable design of the casting lifting table structure, which improves the stability of the equipment. The control system with independent intellectual property rights, multi-functional electrical circuits and programming, and stable performance ensure the smoothness of the production line. Standard SMEMA communication interface can communicate with other automation equipment. SMT loader machine plays a very important role in the SMT assembly line.

The SMD/SMT loader and unloader machine are used as the board loading device for producing circuit boards. It can be used with the standard material box to automatically send the circuit boards stored in the material box to the production line one by one. The pick and place feeder can be used for various circuit boards of different sizes and has wide applicability, high productivity.

TYPES OF LOADER AND UNLOADER

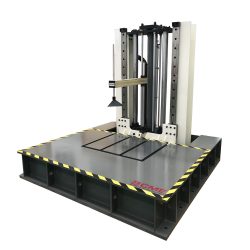

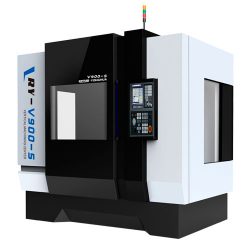

Auto Loader SL400

It is used for the board loading device of SMT production line circuit boards. It can be used with the standard material box to automatically send the circuit boards stored in the material box to the …

Auto UnLoader XL400

It is used for the board loading device of SMT production line circuit boards. It can be used with the standard material box to automatically send the circuit boards stored in the material box to the …

SMT LOADER AND UNLOADER MACHINE ADVANTAGES

In the automated SMT production line, the PCB loader and unloader machines are indispensable machines.There are many advantages of loader and unloader machine:

1. SMT loader machine is recycled and durable which can save time.

2. People-saving: semi-automatic printer machine is filled with the whole frame board, this employee can do other types of work at any time, or one person can print multiple production lines at the same time.For semi-automatic printer machines, only one person needs to take care of multiple production lines. Because it is a cyclic storage board, it can be added at any time without changing the frame again.

3. The size of the machine is small, saving working space.

4. Strong practicality:It can use with semi-automatic printer machine, full-automatic printer machine, regardless of single or double panel.When there is no panel, the automatic alarm function will sound.

5. The reliability is extremely high: Due to the small amount of movement, less wear, and all metal materials.

6. Improve efficiency: When the pick and place machine has a signal and needs PCB, the loading machine will supply the board on time, and the automatic alarm function will not cause the pick and place machine to run idle.

MAINTENANCE OF SMT LOADER MACHINE

The use of loader and unloader machines in the automated SMT workshop has greatly improved the efficiency of production. So how to maintain the loader and unloader machine?

1. Keep the loader and unloader machines free of debris to avoid debris falling into the workbench and causing damage to the machine.

2. Repair and maintenance methods for the gearbox of the loader and unloader machine: the first time it is used for about three months to drain the oil in the gearbox, clean the inside of the gearbox with diesel or gasoline, and put the new smooth oil after it is drained. Add to the middle of the viewing window immediately. It is enough to change the lubricating oil once a year in the future. Too much lubricating oil may cause the gearbox to heat up, and excessive motor load may cause the motor maintenance switch to trip. Too little lubricating oil may cause the gearbox to heat up, increase noise, and the gearbox hangs and is scrapped.

3. Repair and maintenance methods for the motor of the loader and unloader machine head: Do not put water into the motor, nor add diesel oil and liquid organic compounds to the motor, because this can cause the insulation of the motor to be damaged and cause problems.

4. Repair and maintenance methods of the loader and unloader machine trigger chain: The chain may cause the original lubricating oil to heat and volatilize after a long-term operation, and cause the chain to be unbalanced during operation, increase noise, and creep. At this time, you can turn over the sealing plate at the tail end, and add butter or thicker smooth oil to the chain.